Innovative technology continues to create positive change for manufacturing supply chains.This blog summarizes key findings from the 2023 NextGen Solutions report.

Peerless Research Group carried out this survey on behalf of Supply Chain Management Review in order to gain a deeper understanding of the approaches, procedures, and technology that leading supply chain companies are considering using. The report analyzed 74 respondents in September 2023 for the data. This article summarizes critical topics in the report, including cost control, process improvement, and ways to improve accuracy and reduce labor costs.

Supply Chain Survey - Respondent Demographics

Respondent Organizational Role |

Percentage |

|

Corporate/Divisional Manager |

18%

|

|

VP/General Manager |

18%

|

|

Logistics/Distribution Manager |

9%

|

|

Warehouse Manager/Supervisor |

2% |

|

Supply Chain Manager |

9%

|

|

Operations Manager |

8%

|

|

Purchasing/Procurement Manager

|

7% |

|

Other

|

32% |

Supply Chain Survey - Key Findings

Supply Chain Survey - Key Findings

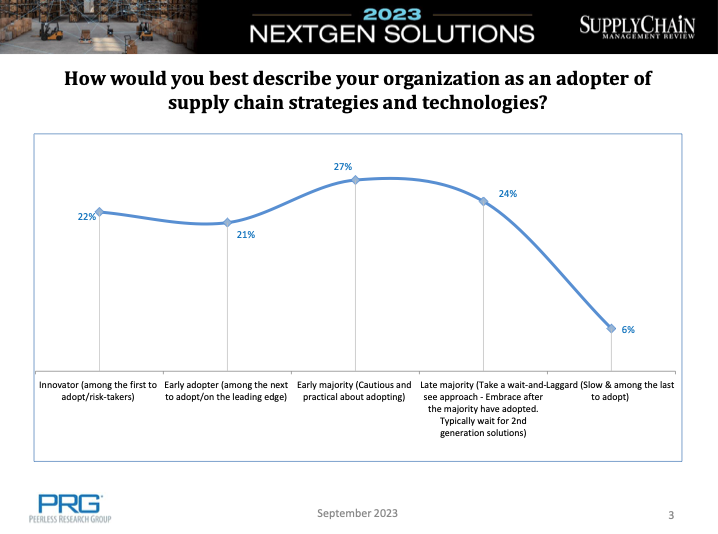

How Many Organizations Are Innovators Versus Slow Adopters?

The survey asked respondents about their firm’s approach to adopting supply chain strategies and technologies. The results, shown in the bell curve chart, indicate that:

- 27% are cautious and practical adopters (early majority).

- 24% take a wait-and-see approach, adopting technology after the majority have already done so (late majority).

The latter often prefer to wait for a 2nd generation solution, indicating a more cautious approach to technology adoption.

The chart reveals a split between innovators (risk-takers who are among the first to adopt) and cautious adopters:

- Innovators make up 22% of respondents.

- Early adopters, who are on the leading edge of adoption, account for 21%.

This data provides insight into organizations' varying approaches when adopting innovations for their supply chain.

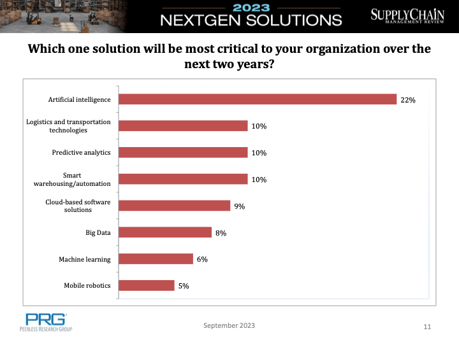

The Most Critical Innovation in the Next Two Years

In response to the question, "Which solution is most critical for your organization over the next two years?"

22% of respondents emphasized Artificial Intelligence innovation, while 10% highlighted logistics and transportation technologies, predictive analytics, and smart warehousing/automation. Respondents noted cloud-based software solutions, big data, Machine Learning, and mobile robotics, ranging from 9% to 5%.

What is the reason for their answers? The responses emphasize that AI will be pivotal across various business functions. Respondents expect AI to streamline warehouse operations, improve production team efficiency, and anticipate shifts in demand. Additionally, they view it as vital for ensuring operator safety and reducing errors.

But AI is only as good as the data you're using to build the models. If you aren't collecting and using accurate, timely, and comprehensive data, your AI models will suffer, and you won't optimize your supply chains proficiently. AI without a digital data collection solution will ultimately fail.

Technology Adoption Means More Data-Driven Insights

Respondents agree that current demand forecasting tools need improvement. They find that the existing software needs to be improved and stress the importance of clear, actionable insights from data for informed decisions and smoother supply chain operations.

Respondents see Generative AI as a pivotal force causing meaningful change. This is due to technological advancements and the need for improved global economy efficiency.

Respondents recognize that prioritizing security is crucial for widespread adoption. Data security is paramount for sustained growth, client trust, and customer demand.

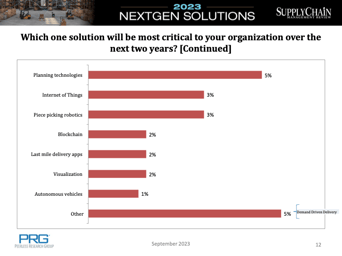

There is a recognition that next-gen technology will be critical to manufacturing supply chains:

- 5% of respondents say that planning technologies like production scheduling, demand planning and forecasting tools, inventory management, and other solutions will play a growing role.

- 3% said the Internet of Things (IoT) and Piece Picking robotics will be critical, with 2% saying last-mile delivery apps and visualization tools will be pivotal in the next two years.

Many of these solutions depend primarily on the quality of data collected, which is where the importance of no-code tools like Alpha TransForm comes in.

With minimal technical knowledge, manufacturers can build customized solutions for production scheduling, forecasting, and inventory management, reducing costs, automating workflows, and time-saving last-mile delivery solutions with enhanced data accuracy.

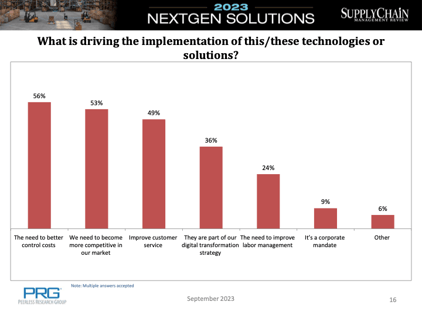

Embracing Technology Adoption for Sustained Competitiveness

When answering what is driving the implementation of this/these technologies or solutions,

- 56% of respondents say the need to control costs better.

- 53% say the need to become more competitive in our market.

- 49% feel that implementing technologies means improved customer service.

- 36% say technologies are integral to their digital transformation strategy.

- 24% note that technologies meet their needs to improve labor management, with 9% saying it’s part of their corporate mandate.

One of the ways of controlling costs is by making the transition to digital forms.

Example: The Costliness of Paper-processes:

Field reps spend 11 hours, and business owners spend 6 hours weekly on paper forms, costing $4,147 per year per rep. This wastes time and may lead to outdated or incomplete data. Switching to a paperless system improves data accuracy and analysis. Automatic data collection and mobile features enhance information quality.

Digital Forms Speed and Efficiency for Manufacturers

The speed and efficiency of digital forms make production processes more efficient and, as a result, benefit a company's commercial competitiveness while meeting customer demand.

- They also save costs by minimizing errors.

- Multimedia features like images and videos enhance clarity, while real-time data access supports quick decision-making.

- Cloud-based accessibility offers flexibility, and workflow automation streamlines operations.

Digital forms are revolutionizing manufacturing. They ensure checklists like Gemba Walk or 5S Audit are consistent worldwide, making it easier to spot patterns and make informed decisions.

>>Looking to build customized solutions that save time and money and improve production speed? Explore our manufacturing productivity tool templates<<

What is the reason for respondents' answers?

Respondents recognize that staying competitive requires adopting new tech for efficiency and cost control. The right technology equates to more efficiency and cost control. Some have reservations about AI, especially GenAI.

However, they acknowledge its importance for quick, insightful decisions using LLMs. Other respondents add that merging big Data and generative AI provides vital insights for operations and customers.

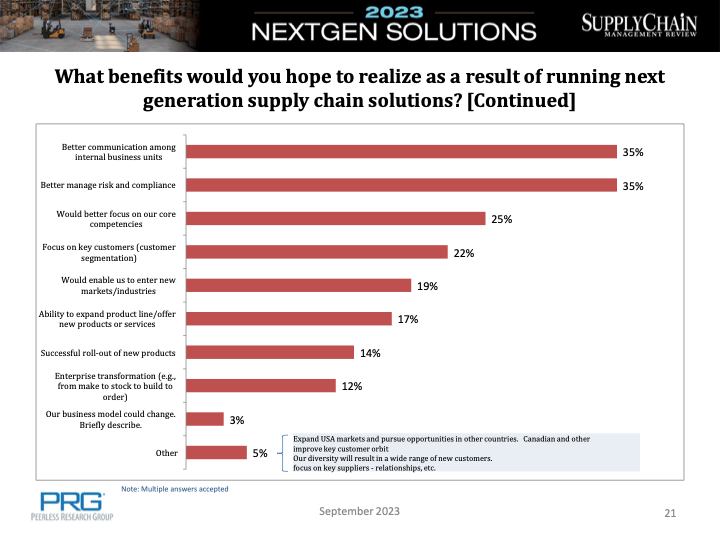

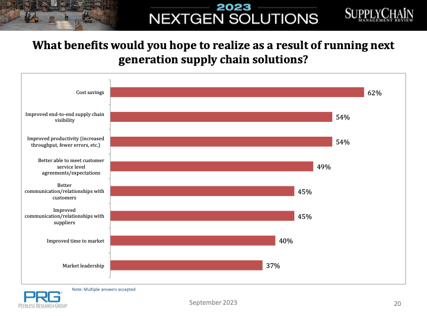

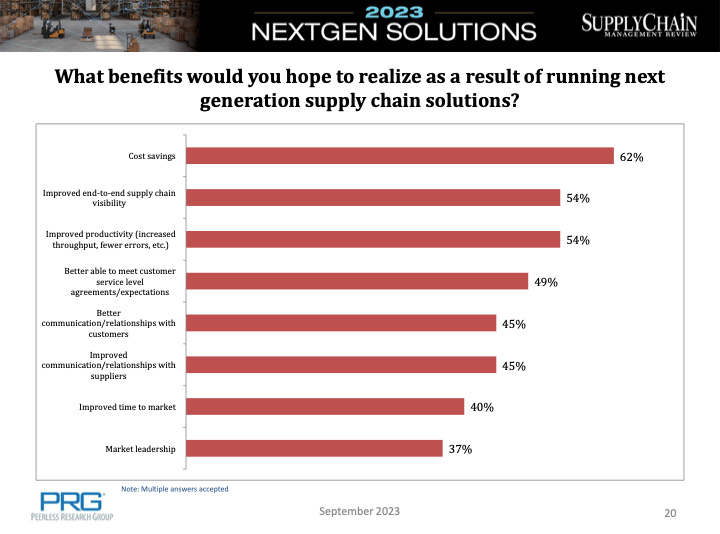

Supply Chain Survey - Benefits Expected

When asked about the benefits of next-generation supply chain solutions, professionals highlighted:

- 62% anticipated cost savings

- 54% emphasized improved end-to-end supply chain visibility and increased productivity (e.g., higher throughput, fewer errors).

- 49% noted better customer service levels.

- 45% cited improved customer communication.

- 45% noted that technology enhanced relationships and communication with suppliers.

The Crucial Role of Big Data and Supply Chain Analytics

As the Computer Goods and Technology online publication notes, big data and supply chain analytics are crucial for businesses now and in the future. "They create efficiencies, lower costs, and enhance customer service," says Douglas Kent, EVP of Strategy and Alliances for the Association for Supply Chain Management (ASCM).

"Data and analytics tools are essential now. Supply chains remain volatile and unpredictable. In-depth forecasting can help reduce [supply chain] disruption-related risks," Kent adds.

What are the Objectives/Goals for Implementing Cutting-Edge Solutions?

The main objectives and expectations for implementing NextGen technologies include:

- Optimizing more employee deployment for increased revenue generation.

- Balancing risk-taking with a reliable supply chain and improved supply chain planning.

- Achieving cost savings while maximizing profits and improving customer service.

- A core objective is that innovative technology should help with tracking operations, efficient resource use, and implementing improved processes.

Respondents highlighted that advanced technology would drive expansion in the U.S. and Canada to meet market demands.

Key themes in respondents' answers included:

- Strengthening a continuous improvement culture.

- Their goals are to enhance processes and increase productivity with controlled costs.

- There was also an emphasis on customer satisfaction.

Leveraging advanced technology, reducing costs, and increasing productivity are central goals, all while maintaining competitiveness in the industry.

Respondents focused on AI-driven cost reduction, risk analysis, flexibility, and machine learning. The overarching objective is to be a leading service organization through innovation, efficiency, and customer-centric practices.

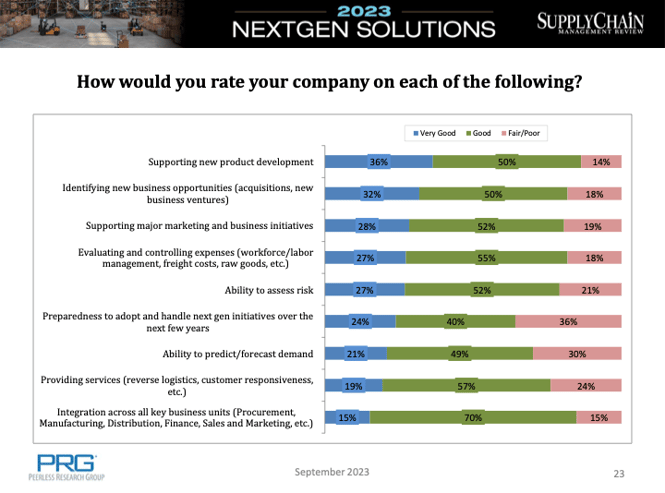

Supply Chain Survey Results - How Does Your Company Rate?

When responding to the question, “How would you rate your company on each of the following” [statements],

- 36% noted their companies were very good at supporting new product development, with 50% remarking their company provided good/adequate support with 14% saying that their company was fair/ poor.

- 27% remarked that their company was very good at evaluating and controlling expenses, including (workforce/labor management, freight costs, raw goods, etc.). 55% answered that their company was adequate/good at expense control, with 18% saying their company was fair/poor.

- 24% noted that their company had "very good" preparedness to adopt to handle next-gen initiatives over the next few years. 40% reported their company's adequacy at this, with as much as 36% saying their company was fair/poor.

- 21% remarked that their company was very good at predicting/forecasting demand. 49% "adequate/good," with as much as 30% commenting fair/poor.

In summary, these results suggest that while less than 50% noted that their company was very good at supporting new product development, there is still room for improvement.

With just 24% noting their company had "very good" preparedness to adopt next-gen initiatives over the next few years, this suggests a need for more technology skills in building solutions, implementing, and integrating them.

With a low barrier to learning, building, and deploying technology across an organization, Alpha Transform allows employees to create, test, and deploy solutions to increase productivity and cost efficiency.

How Has COVID-19 and the Current Financial Climate Influenced New Technology Adoption?

When respondents were asked, “How has COVID-19 and the current economic climate changed your company's approach to adopting NextGen solutions for your supply chains?”

- 44% said they are scrutinizing investments and will move forward cautiously.

- 35% replied that they are moving forward with new investments this year.

- 20% noted that they are unsure of their plans at this time.

- 8% say they plan to upgrade existing NextGen solutions instead of buying new ones.

Other responses reflected a reluctance to invest and a preference for outsourcing supply chain activities.

- 6% indicated they would delay NewGen technology investments until financial environment clarity emerges due to the pandemic.

- Another 6% plan to increase outsourcing of supply chain operations.

- 3% have called off all investments in NewGen Tech this year.

- 8% of respondents are doing a combination of all the above.

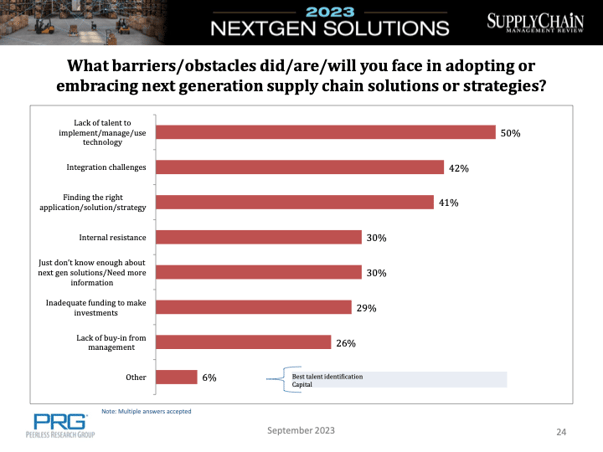

Barriers to Adopting Next-Gen Manufacturing Supply Chain Solutions

Barriers to Adopting Next-Gen Manufacturing Supply Chain Solutions

When asked about the obstacles faced in supply chain solution adoption, responses included:

- 50% cited a need for more tech-savvy talent as a hurdle.

- 42% pointed to integration challenges.

- 41% struggled with finding the correct application or strategy.

- Notably, 30% faced internal resistance.

- Another 30% lacked knowledge about next-gen solutions or needed more information.

How Low-Code and No-Code Platforms Resolve These Challenges

Alpha Transform and similar platforms empower non-technical employees to create custom applications for efficient data capture, seamlessly integrating with existing manufacturing systems.

These platforms empower non-technical staff, address integration challenges, and facilitate the implementation of practical applications and strategies to drive business initiatives.

Upskilling and Engagement:

In 2022, 70% of organizations faced a tech skills shortage, hindering adoption. Low-code and no-code platforms provide a solution by enabling non-technical employees to create solutions for business challenges, regardless of their technical background.

Without complex coding, more employees can participate in tech projects, gaining new skills and improving problem-solving abilities.

Rapid Problem-Solving:

Low-code and no-code platforms positively impact problem-solving. They engage more employees to reduce IT workload while providing opportunities to shine. Citizen developers are employees who can quickly learn no-code platforms.

By designing functional apps, the workforce increases productivity across manufacturing and business office processes. Their empowerment leads to quicker, more accurate solutions, fostering a culture of continuous improvement.

Enhancing Collaboration and Innovation:

These platforms foster a collaborative environment for cross-functional teams. They enable business and IT professionals to co-create solutions, breaking down silos and promoting innovation.

This approach accelerates development, resulting in more robust, tailored solutions that meet specific organizational needs. By enabling teams to work together effectively, these platforms enhance efficiency and creativity in the development process, reducing the technology adoption barrier.

No-Code Development Use Cases in Manufacturing:

Shopfloor Management:

- Manufacturers can use safety checklists to ensure adherence to safety protocols, including 5S/6S checks.

- No-code solutions support shift handovers, providing employees with critical task-related information.

- Applications enable more visibility on who is doing what and who can be assigned based on workgroups, areas, and skill sets.

- Permissions can control access to specific apps.

- Skills development can also be automated based on recorded or live virtual training sessions.

Assembly:

- Standard Operating Procedures (SOPs) form and enforce standard work protocols, ensuring efficient completion of equipment control, machine setups, and Gemba walks.

- Assistance Request Tools reduce machine downtime, boost productivity, and streamline the request process.

Quality Management:

- In manufacturing, a crucial process involves inspecting products for defects and recording material issues. Low-code or no-code solutions designed for quality checks streamline data collection.

- Low-code/no-code solutions facilitate efficient material tracking and quality validation in manufacturing. They offer rapid workflow setup and adaptable changes for manufacturing line validation processes.

- These tools enable rapid analysis through dashboards or data visualization. Better data quality aids predictive analytics. This allows companies to foresee maintenance needs and replenish materials before supplies run low.

Tackling Labor Shortages:

- Manufacturers face labor challenges, needing to attract younger workers and boost productivity. Low-code apps can help achieve both objectives. They empower millennials to troubleshoot independently and streamline tasks for existing employees.

Bottom Line: Why Adopting NewTech is Essential for a Company’s Competitiveness

Manufacturing and supply chains benefit from advancing technology. No code and other innovative technologies can lower barriers to adoption.

The 2023 NextGen Solutions report, based on 74 surveys, highlights core areas like cost control and process improvement while underlying AI and other technologies' importance. Embracing technology is essential for industry competitiveness.

Comment