Custom solutions that match your processes, integrate with your manufacturing operations and achieve continuous improvement.

* Your email is safe. We never sell or share our user data

Your manufacturing processes, data, and systems are all considered when we craft custom solutions for your unique data collection, analysis or workflow needs. You'll find our intelligent apps to be:

Whatever you need, our technology can handle the job. We can digitize paper forms in hours or build complex systems that quickly generate dashboards, enable root cause analysis, or initiate rework or repairs. And every app can work on a manufacturing floor with or without an Internet connection.

We'll take best-in-class solutions and quickly perfect them for your unique process and continuous improvement. We can tie into your existing MES or ERP, or build a more advanced solution -- all with rapid implementation.

You can take advantage of our freemium product tier and pre-built manufacturing solutions for free, no credit card required.

Alpha Software will develop the right-sized solution that matches your existing process, budget, and requirements. We'll build mobile apps and desktop dashboards that save workers time recording quality data, and speed data insights for quality managers.

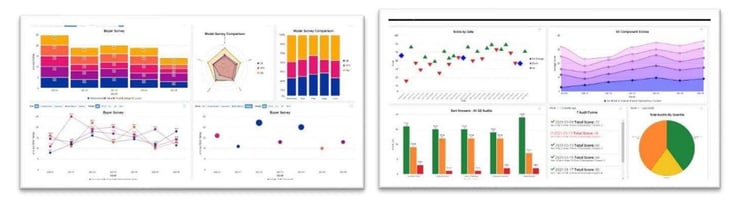

For example, our Quality Management Solution saves workers hours recording data on the production floor, and generates reports that speed data insights for quality managers. The apps shave hours off inspections, automatically recording time/date/location information, and speeding the collection of photos, measurements, bar code scans, digital signatures, and more. Data can be shared instantly in an Excel report or connected to your existing systems and databases. A built-in analytics engine generates visual dashboards that drive lean manufacturing and continuous improvement. Quality managers struggling with expensive ERP modules, hard-to-use ERP interfaces, or limited offline capability in their ERP, can add value to their system with our powerful, easy-to-use mobile apps. Learn how we can help enhance the value of your ERP system.

Our solutions take data collection and analysis digital, streamlining your employees' work. Whether you're digitizing one paper form or modernizing the factory floor, we'll match your needs and budget.

"With industrial demand high, as of June, there’s a shortage of almost 600,000 stable manufacturing jobs waiting to be filled in manufacturing businesses nationwide."

- Kevin Stevick,

President & CEO, SteelCraft

in Forbes

Read how a quality control manager digitized paper forms, cut costs by $145,000, and increased data accuracy and insights.

Gemba Walks • 5S Audits • Workstation Audits • Equipment Maintenance • Regulation and Compliance • ISO Certification

Product Inspections • Non-Conformance Reports • Yellow Sheets • Temporary Deviation Authorizations • Shortage Sheets • Per Unit Reporting

Work in Progress Tracking • Supplier Defects • Material Orders • Inventory Management • and more.

“Previously, I could spend hours looking through boxes of paper and storage for a specific date, and for assembly shift information that I needed for my root cause analysis to try to figure out what happened when something wrong.

Now I can just search by date and pull up the form pictures. It's helped tremendously.”

- John Ng

Manager of Quality Control

Igloo Coolers

"We have been very pleased with our new software system.

All of our team have found it user-friendly and the flexibility enabling us to adjust the system specific to our individual product types has really meant we have been able to effectively bespoke it to our way of working. "

- Neil Brandrick

Director

JC Payne Trucks

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/