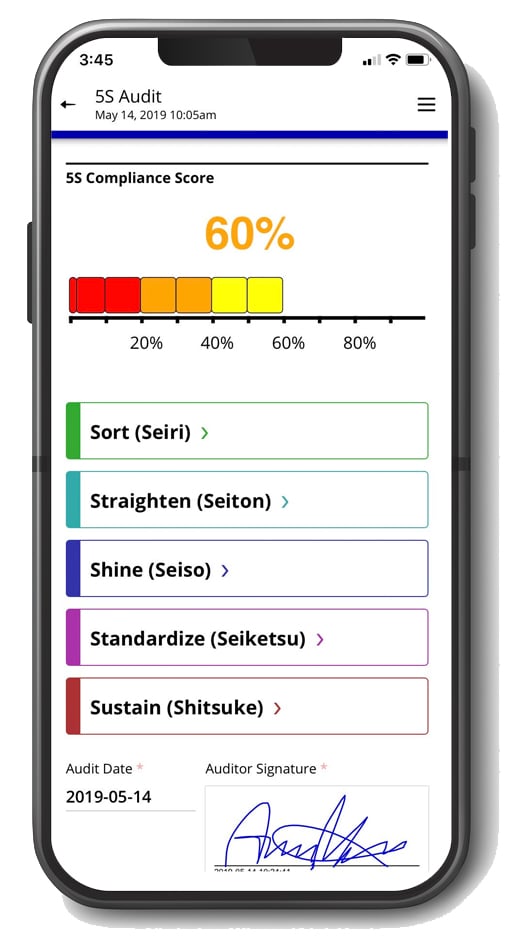

This digital checklist helps team members evaluate and score the current state of 5S implementations faster than using paper forms. Data collection is more comprehensive and detailed. Managers can instantly access visual dashboards for continuous improvement and tracking of progress.

This digital checklist helps team members evaluate and score the current state of 5S implementations faster than using paper forms. Data collection is more comprehensive and detailed. Managers can instantly access visual dashboards for continuous improvement and tracking of progress.

Modernize your data collection and analysis capabilities while ensuring lean manufacturing and Six Sigma processes are followed with this powerful llean manufacturing tool.

A digital 5S audit solution for continuous improvement.

By going digital, you'll standardize and sustain continuous improvement efforts by evaluating the impact of improvements and comparing results against previous audits.

Our 5S mobile app can:

This digital 5S checklist works offline, so your employees are always produtive, even without a WiFi or cell signal. The app can also be fully cutomized to capture information unique to your factory, process, or safety requirements. Data or reports can easily be shared with the team automatically or with a click.

This free 5S Audit digital checklist solution helps assess the state of your 5S implementation, reduce unnecessary items in working areas, and improve the working environment. This 5S Audit mobile app evaluates and scores key indicators in each of the five components of a 5S program in real-time. Each audit process is automatically scored, so that progress can be measured over time. You can also customize this Alpha TransForm 5S audit template for your needs.

Evaluate and score the current state of your 5S implementation in lean manufacturing with this free digital 5S audit checklist that features:

Before you can start improving workflow processes, you must identify areas in need of improvement. While regular 5S audits are a helpful tool, managers must be able to conduct these audits on a routine basis and track progress over time to ensure continuous improvement.

Make your 5s audits a replicable success by

Alpha Software is the ideal partner because our 5S solution will guide employees through a comprehensive checklist mapped to your process. You'll benefit from custom reports that speed analysis.

A key part of Lean manufacturing and often used as a foundational element within a Lean Six Sigma approach, 5S Audits offer a system for visual inspections of workspaces. They are practices to ensure that work is performed efficiently, effectively, and safely. While many companies still use paper, digital checklists for 5S systems save time when doing inspections and data analysis.

5S principles help eliminate unnecessary items, time, movement, and inventory on a daily cadence. The effort also improves workplace organization as a whole. 5S Standards result in more efficient operations and continuous improvements.

Derived from five Japanese words, the term 5s comprises:

5S audits or inspections provide an actionable framework that allows organizations to conduct an ongoing analysis of work processes. It's often used as part of lean methodology for process improvement or continuous improvement.

By identifying inefficiencies and opportunities for improvement through this audit, you can greatly improve overall efficiency and eliminate roadblocks.

Benefits of 5S implementation include:

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/