Gemba Walk Checklist for Manufacturing: Steps & Templates

Learn to conduct effective Gemba walks in manufacturing with structured checklists and digital templates. Streamline observations and reporting tod

Learn to conduct effective Gemba walks in manufacturing with structured checklists and digital templates. Streamline observations and reporting tod

Key Takeaways

- Gemba walks are structured workplace inspections where managers use checklists to verify safety and operational standards while directly observing and engaging with frontline workers to identify improvement opportunities.

- Paper-based Gemba inspection processes create delays, documentation gaps, and data loss that slow corrective actions and increase compliance risks in manufacturing environments.

- Digital inspection templates enable real-time data collection during Gemba walks with photo capture, GPS tracking, barcode scanning, and offline functionality for reliable field operations.

- Mobile inspection apps accelerate maintenance cycles through instant reporting, automated workflows, and seamless integration with existing business systems.

- Alpha TransForm is a no-code tool that transforms paper Gemba walk inspection forms into customizable mobile apps that allow managers to customize in minutes, delivering offline reliability and proven ROI for manufacturing operations.

Why Gemba Walks Are Essential in Manufacturing

Continuous improvement is the lifeblood of every successful manufacturing operation. And one of the simplest, most effective ways leaders keep things moving forward is through the Gemba walk.

Gemba—Japanese for “the real place”—means stepping out onto the production floor, where value is created, to see things firsthand. Instead of relying on reports, managers walk the floor, watch how work actually gets done, and talk with employees. The goal is to spot inefficiencies, strengthen safety, and raise quality standards.

The problem is, too many Gemba walks lose their punch when managers still use paper checklists. Clipboards can’t capture photos, signatures, or detailed notes. And by the time observations are written up and passed along, the situation on the floor may have already changed, letting chances for improvement slip through the cracks.

That’s where digitizing the Gemba walk makes all the difference. Instead of paperwork piling up, digital templates can enable insights to flow in real time, turning an old-school routine into a modern, data-driven improvement cycle.

The Limitations of Paper-Based Gemba Walks

For years, manufacturers have relied on paper forms for audits and inspections, and the resulting inefficiency often stops Gemba walks from delivering the real improvements they’re supposed to.

Paper slows everything down because observations have to be typed into spreadsheets later, which delays action. Records also get lost or filled out halfway, leaving compliance documentation incomplete. Without timestamps, signatures, or photos, accountability is weak, and stacks of paper make it almost impossible to spot trends across shifts or sites.

The result is that managers end up buried in paperwork instead of driving improvements. Corrective actions take longer to close, safety upgrades get delayed, and opportunities to cut waste often slip away.

To get around these problems, more manufacturers are moving to mobile-first digital checklists. With offline capability built in, they make data capture immediate, accurate, and verifiable.

Core Elements of a Gemba Walk Checklist

A structured Gemba walk checklist ensures consistency across departments and shifts while also focusing the manager’s attention on what really matters. While every manufacturing plant has unique standards, the most effective Gemba walk checklists cover the following core elements:

Safety

Managers look for anything that could put employees at risk, like blocked emergency exits, missing PPE, or tools being handled the wrong way. Spotting these issues early helps prevent accidents and reinforces the message that safety comes first.

Equipment Condition

During a walk, leaders check whether machines are being used correctly, serviced on schedule, and kept free of leaks or visible wear. This protects workers and helps avoid costly downtime from unexpected breakdowns.

Workflows

The checklist should prompt managers to watch how materials, tools, and resources move across the floor. Extra steps, wasted motion, or unnecessary delays stand out more clearly when seen in real time.

Quality Compliance

Quality Compliance

Every product has to meet the company’s standards, and compliance checks keep that in focus. A strong checklist includes reviewing whether testing protocols are followed, documentation is up to date, and quality requirements are consistently applied.

Employee Engagement

Talking with operators is one of the most valuable parts of a Gemba walk. Direct conversations reveal day-to-day challenges and often surface practical suggestions for improvements. It also shows employees that their input matters, which builds collaboration and trust.

A structured Gemba walk checklist helps refine manufacturing processes. (Image courtesy of Machinery lubrication).

5S Practices

The final piece is checking the 5S: Sort, Set in Order, Shine, Standardize, and Sustain. A well-organized workspace looks better and reduces wasted time, prevents mistakes, and keeps processes running smoothly. Attention to 5S implementation reinforces discipline across the team.

Steps to Conduct a Gemba Walk

When done well, a gemba walk should feel natural, and it becomes part of an organization’s improvement culture rather than an isolated task. The steps below outline a structure that both new and experienced managers can follow:

Step 1: Define Objectives & Prepare Checklist

Every walk should begin with a clear purpose. Are you focusing on safety today? Or is quality the priority? Having clarity ensures that observations are meaningful.

Use a predefined checklist that matches your objective, but allow space for open-ended notes. With digital templates, this preparation becomes simpler because questions, photos, or conditional follow-ups can be preprogrammed.

Step 2: Walk the Floor & Talk to Employees

Engage directly with the workplace. Resist the urge to intervene immediately unless there’s a safety risk. The purpose of the walk is observation and understanding, not correction in the moment.

Workers on the floor often have valuable insight into recurring issues. Ask open-ended questions such as “What slows you down?” or “What do you think could make this line run more smoothly?”

Step 3: Record Findings & Follow Up

Automatically capture comprehensive inspection data including photos of observed issues, precise timestamps, GPS location tags for tracking across large facilities, and digital signatures for verification.

Review results soon after the walk and share them with supervisors and operators. Assign corrective actions clearly with owners and deadlines. The faster the follow-up, the stronger the impact.

Step 4: Close the Loop

Schedule return visits to confirm improvements are implemented. Gemba walks should reinforce a culture of accountability and continuous progress.

Why Manufacturers Choose Digital Gemba Walk Checklists

Instead of juggling paper checklists, cameras, and separate documentation, inspectors can capture everything (e.g., photos, signatures, barcodes, and GPS data) in one place.

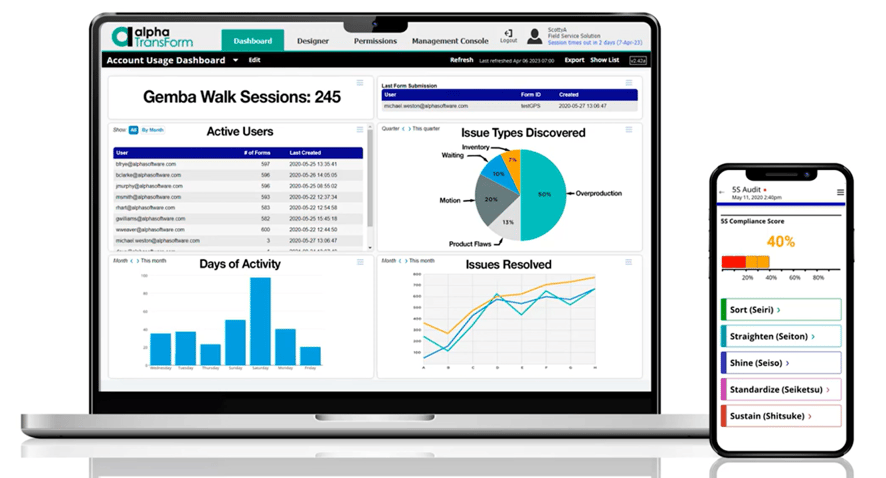

Now, rather than wait days for someone to type up reports, managers see equipment trends in real time through dashboards. They can also spot recurring problems, track completion rates, and catch issues before they become failures.

The shift from paper to digital means faster fixes, better accountability, and less time wasted on paperwork. Teams can customize templates in minutes and expand from there, turning Gemba walks into a more efficient operational process.

Gemba Walk Checklist App Template

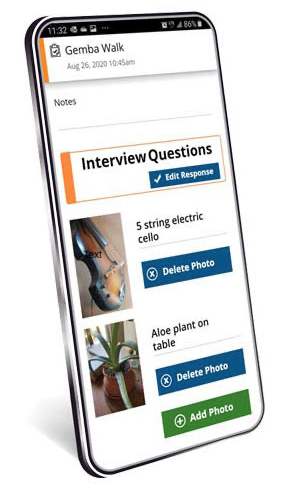

Digital templates make Gemba walks a lot easier, and modern Gemba walk apps let managers capture observations on phones or tablets far faster than paper forms allow.

All documentation lives in one digital workflow where notes, photos, measurements, and signatures sync together automatically. These tools are designed specifically for manufacturing environments where connectivity can be spotty and conditions are demanding.

For example, our very own Alpha TransForm Gemba Walk App exemplifies this digital transformation with features built specifically for shop-floor realities. The pre-built template accelerates observation collection during facility tours while offering easy customization to match unique processes and requirements.

Key features include:

- Offline data capture allows inspectors to complete Gemba walks even in areas with poor connectivity, with all information syncing automatically once back online.

- Image capture with annotation and markup lets teams document issues directly on-site, adding notes or highlights to photos for clearer communication.

Modern Gemba walk apps let managers capture observations on phones or tablets far faster than paper forms allow.

- Voice-to-text, audio recording, and digital signatures make it easy to capture observations, approvals, or feedback during the walk without slowing down the process.

- Automatic time, date, and GPS stamping provide accurate context for every observation, ensuring compliance and traceability of Gemba walk findings.

- Built-in calculations and measurements help inspectors quickly validate data on the spot, reducing errors and supporting immediate decision-making.

You can get free access to the app and start using it right away—then adapt it to your team’s needs.

Alpha TransForm for Seamless & Efficient Processes

We designed Alpha TransForm to transform Gemba walk inspections from time-consuming paperwork into streamlined digital workflows that deliver immediate value.

Operations leaders choose our platform because we eliminate the fundamental challenges that slow them down: lost forms, data entry delays, and waiting for inspection results that should drive immediate maintenance decisions.

Our offline-first approach ensures inspections continue uninterrupted in warehouses, production floors, and remote facilities. Operations leaders can build custom equipment inspection apps in under 30 minutes using our no-code platform without waiting for IT resources.

Igloo reduced quality control costs by $145,000 using Alpha TransForm-powered inspection apps, while also boosting accuracy and team efficiency. By integrating directly with their existing maintenance and ERP systems, inspection data now flows seamlessly into core operations—automatically triggering work orders and compliance reports without manual effort.

Igloo reduced quality control costs by $145,000 using Alpha TransForm-powered inspection apps, while also boosting accuracy and team efficiency. By integrating directly with their existing maintenance and ERP systems, inspection data now flows seamlessly into core operations—automatically triggering work orders and compliance reports without manual effort.

From equipment inspections and 5S audits to Gemba walks and safety checklists, our platform scales with operational needs while maintaining simplicity that keeps business users productive. Ready to transform your manual processes into digital workflows that drive operational excellence?

Manufacturing companies have reduced quality control costs significantly using Alpha TransForm-powered applications.

Frequently Asked Questions (FAQs)

What is a Gemba walk in manufacturing?

A Gemba walk is when leaders physically visit the production floor to observe workflows, equipment conditions, and employee practices, to identify waste, improve safety, and foster continuous improvement.

Why use a checklist for a Gemba walk?

A checklist ensures consistency across Gemba walks, keeps observations focused, and provides traceable records. Digital checklists strengthen accountability by adding timestamps, photos, and signatures.

How often should manufacturing leaders perform Gemba walks?

Most facilities benefit from weekly Gemba walks at a minimum. Some organizations schedule them daily for high-priority areas or monthly for broader oversight.

What are the drawbacks of paper Gemba walk checklists?

Paper forms slow reporting, risk being lost or incomplete, and make trend analysis difficult. These limitations delay corrective action and reduce accountability.

How does Alpha TransForm improve the Gemba walk process?

Alpha TransForm is a no-code tool that turns paper checklists into mobile-first apps that work offline. Organizational leaders and managers can create customized apps in minutes to capture photos, barcodes, and signatures, and instantly generate reports and dashboards for real-time decision-making during Gemba walks.

Comment