Learn how to run practical Kaizen events in manufacturing with templates, examples, and checklists. Digitize your continuous improvement with Alpha TransForm.

Key Takeaways

- Kaizen events are focused, short-term improvement workshops that eliminate waste, optimize workflows, and build a culture of continuous improvement.

- Structured templates provide the framework for planning and executing successful Kaizen events. They cover objectives, team roles, metrics, root cause analysis, and implementation plans.

- Detailed checklists guide teams through preparation, execution, and follow-up phases to ensure lasting results and accountability.

- Digital platforms like Alpha TransForm replace paper-based Kaizen documentation with mobile apps that work offline, capture real-time data, and integrate with existing systems.

Why Kaizen Events Drive Manufacturing Excellence

Traditional approaches to process improvement often move too slowly or require extensive consulting resources that small to mid-sized manufacturing operations can't afford. Kaizen event flips this model by bringing cross-functional teams together for intense, focused problem-solving sessions that deliver measurable results in days, not months.

These structured workshops target specific bottlenecks, quality issues, or safety concerns with a bias toward immediate action and rapid implementation. The power of Kaizen lies in its accessibility.

Rather than waiting for capital investments or system overhauls, teams use existing resources to identify and eliminate waste in real time. This approach builds problem-solving capabilities across the manufacturing organization.

Essential Kaizen Event Template Components for Manufacturing Teams

Templates create consistency and capture knowledge, making each Kaizen event more effective than the last. A well-designed template guides teams through planning elements without reducing creativity or problem-solving.

Core Kaizen event template components include:

- Event scope & objectives: A clear definition of the problem statement, target area, and desired outcomes aligned with business goals.

- Team structure: A designated leader, facilitator, team members from different functions, and an executive sponsor.

- Baseline metrics: Current state measurements for cycle time, defect rates, inventory levels, safety incidents, or other relevant KPIs.

- Timeline and milestones: A structured agenda covering process mapping, root cause analysis, solution brainstorming, implementation, and verification.

- Data collection tools: Place importance on value stream maps, spaghetti diagrams, time observation sheets, and quality check sheets.

Well-designed Kaizen event templates guide teams through planning

elements while capturing knowledge that makes each event more effective than the last.

- Root cause analysis frameworks: 5 Whys questioning, fishbone diagrams, and Pareto charts to isolate actual problems.

- Action planning: Be clear about implementation steps, assignments of responsibilities, resource requirements, and target completion dates.

Example Kaizen Event Manufacturing Templates You Can Use

You can download these templates directly from the sources and use them immediately for your Kaizen event planning and execution at your manufacturing facility.

University of Iowa Healthcare - Kaizen Event Template

The University of Iowa Healthcare Kaizen Event Template provides a structured PDF format that includes sections for the Project Charter, Implementation Plan (with action items limited to 2-week timeframes), Lessons Learned, and Looking Ahead for identifying additional improvement opportunities discovered during the event.

Use this template when you're planning a focused 3–5-day Kaizen event, need to document team member roles and responsibilities, track implementation actions, and gather feedback on what worked and what didn't during your rapid improvement event.

University of Massachusetts Boston - Kaizen Templates Suite

The UMass Boston Kaizen Templates Suite offers three distinct templates for different phases of the Kaizen process: the Kaizen Profile Template for pre-event problem assessment and gap analysis, the Kaizen Closure Template for 2–6-month follow-up evaluations, and the Newspaper Template for real-time task tracking and responsibility assignment throughout the event.

Use these templates when you need a comprehensive approach to managing your Kaizen event from initial planning through long-term sustainability, ensuring proper documentation at the pre-meeting phase, during the event itself, and during follow-up stages to verify that improvements remain effective over time.

How to Develop Your Own Kaizen Event Template for Manufacturing

While the templates above provide a strong starting point, manufacturing facilities often need a customized version that reflects their production processes, equipment, safety standards, and operational culture. Here’s how to build a Kaizen event template tailored to your plant.

Step 1: Gather Input from Stakeholders

Start by interviewing the people who will use the template on the factory floor. Talk to production supervisors, line operators, maintenance techs, quality engineers, and safety coordinators.

Ask what worked during past Kaizen events, where documentation slowed them down, and what plant-specific details must always be captured such as machine IDs, takt time targets, or safety constraints. This prevents you from designing a template that seems neat in theory but doesn’t match the realities of a manufacturing environment.

Step 2: Define Your Template’s Core Sections

Structure the template around the three main phases of a manufacturing Kaizen event: Pre-Event Planning, Event Implementation, and Post-Event Follow-up.

Within each phase, define the core elements your plant needs, such as current state mapping, root cause analysis, downtime measurement, waste identification, or standard work updates.

Step 3: Incorporate Your Organization’s Requirements

Embed requirements that are specific to your manufacturing facility. If your plant must document equipment numbers or production line designations, include those fields. If engineering sign-off is required before modifying machinery or changing standard work, add the appropriate authorization blocks.

If your facility must comply with International Organization for Standardization (ISO), Occupational Safety and Health Administration (OSHA), or internal safety standards, include checkboxes or compliance statements. The goal is to bake all necessary documentation into the template so no one has to hunt for missing information during the event.

Step 4: Keep It Simple & Scannable

Design the template to be clear and fast to complete, especially since Kaizen events in manufacturing often happen on the shop floor with noise, interruptions, and time pressure. Use clear section headers, consistent formatting, and enough spacing for handwritten notes. Avoid plant-specific jargon unless it’s universally understood, and consider adding definitions for terms like cycle time, changeover time, or first-pass yield.

Each section should answer one straightforward question such as: What defect or bottleneck are we eliminating? Which machines or lines are involved? What measurable target defines success? When will we test the new process?

Step 5: Test with a Pilot Kaizen Event

Run a pilot event using the new template. Include both experienced continuous improvement leaders and frontline operators who have never participated in a Kaizen before.

After the event, hold a short debrief focused only on the template: Which sections were unclear? Which details disrupted workflow? What fields were unnecessary? Did the template support faster problem solving on the line? Use this feedback to refine the design before using it plant-wide.

Step 6: Build in Version Control & Continuous Improvement

Your Kaizen template should evolve just like your processes. Create simple version numbers (v1.0, v1.1, etc.) and date each release. After every few events, review how teams used the template. Identify sections that go untouched, questions that repeatedly cause confusion, or new plant requirements such as updated safety procedures or new equipment.

Plan an annual review to ensure the template stays relevant, practical, and aligned with your manufacturing goals.

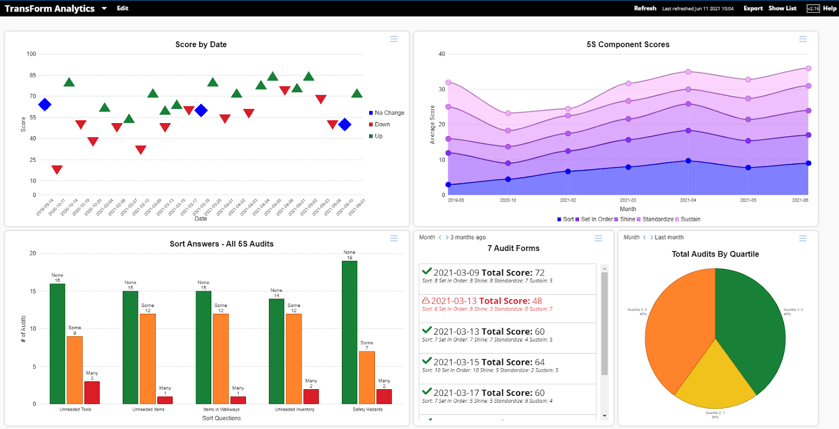

How Alpha TransForm Accelerates Your Kaizen Program

Alpha TransForm lets manufacturing teams turn their Kaizen event templates into fully functional mobile apps without coding or IT delays. Using the no-code builder, you can convert your existing paper forms into a digital Kaizen workflow in minutes, allowing operators, engineers, and supervisors to document improvements directly on the factory floor.

The platform’s offline-first design keeps the app reliable during Gemba walks, line observations, equipment inspections, and time-studies in areas where Wi-Fi or cellular coverage is weak. Teams can capture equipment photos, cycle-time measurements, defect counts, operator notes, and digital signatures right in the app, and all data syncs automatically when connectivity returns. This eliminates transcription errors and ensures every improvement action is traceable.

Alpha TransForm's no-code mobile app builder transforms existing paper templates into professional mobile

apps in minutes, accelerating your entire Kaizen process without IT bottlenecks.

Custom workflows let you automate the follow-up process. Conditional logic routes action items to maintenance, engineering, or quality, automated alerts highlight overdue tasks, and dashboards help leaders track trends across multiple Kaizen events. Built-in tools like photo documentation, barcode scanning for machine IDs, GPS timestamps, and signature capture provide the evidence required for audits, ISO compliance, and continuous improvement reporting.

Kaizen app data integrates with enterprise resource planning (ERP), manufacturing execution systems (MES), quality management systems (QMS), and business intelligence (BI) platforms, creating a unified source of truth for plant-wide improvement initiatives.

The free tier supports up to 3 users and 35 forms monthly—ideal for pilot Kaizen events. Business plans start at $30 per user monthly with unlimited forms, full offline capabilities, and customer success support, while enterprise plans offer advanced security and specialized onboarding for large manufacturing operations.

Frequently Asked Questions (FAQs)

What is the typical duration of a manufacturing Kaizen event?

Most Kaizen events run 3–5 days with a dedicated team focus. Shorter "rapid improvement" events may be completed in 1–2 days for narrowly scoped problems, while complex challenges occasionally require a whole week.

How many people should participate in a Kaizen event?

Practical Kaizen teams typically include 5–8 members representing different functions that touch the target process. Include operators with hands-on experience, maintenance technicians, quality inspectors, supervisors, and support staff from planning or materials.

Smaller teams move faster and reach consensus more easily. Larger teams risk becoming unwieldy. Always include at least one person with authority to approve changes and allocate resources.

What metrics should we track during Kaizen events?

Focus on metrics directly tied to your event objectives. Common manufacturing measurements include cycle time, changeover time, first-pass yield, defect rates, equipment uptime, labor hours per unit, inventory turns, floor space utilization, and safety incident frequency.

Establish clear baseline measurements before the event begins, then track the same metrics during and after implementation to quantify improvements. Visual management boards showing real-time performance help sustain gains.

How do we prevent improvements from fading after a Kaizen event ends?

Sustainability requires disciplined follow-up. Update standard work documents immediately and train all shifts on the new procedures.

Implement visual controls that make deviations obvious, assign clear ownership for each improvement, conduct regular audits to verify adherence, and address problems quickly when they surface.

Why should manufacturers choose Alpha TransForm for Kaizen event management?

Alpha TransForm eliminates the paper chase that undermines continuous improvement efforts. Our no-code platform lets operations teams build custom mobile apps for Kaizen documentation, checklists, and audits without relying on IT.

Our patented offline technology ensures reliable data collection everywhere on the factory floor, with photo capture, timestamps, and digital signatures providing objective evidence.

*Note: Pricing and/or product availability mentioned in this post are subject to change. Please check the retailer's website for current pricing and stock information before making a purchase.

Comment