Compare the top 3 manufacturing inventory management software including Alpha TransForm, Fishbowl, and Katana. Find your best solution today.

Compare the top 3 manufacturing inventory management software including Alpha TransForm, Fishbowl, and Katana. Find your best solution today.

Key Takeaways

- Manufacturing operations require inventory software that works offline, supports barcode scanning and photo capture, and can be deployed rapidly without IT bottlenecks to achieve fast ROI.

- Fishbowl offers manufacturing inventory control with deep ERP integration, making it suitable for companies with dedicated IT resources and complex production workflows.

- Katana provides cloud-based inventory visibility with a user-friendly design, ideal for small to medium manufacturers seeking integration with e-commerce platforms.

- Alpha TransForm stands out by empowering business users to transform manual inventory checklists, 5S audits, and equipment inspections into mobile apps that function flawlessly offline.

Platform Overviews

Managing inventory effectively can make or break manufacturing operations. Tracking raw materials, monitoring work-in-progress, or conducting equipment inspections can be made more efficient with the right software.

The best manufacturing inventory management software must work reliably offline, deploy quickly without technical expertise, and deliver measurable results from day one. After extensive research, we've identified the three platforms that truly deliver for manufacturing teams: Fishbowl, Katana, and Alpha TransForm. Let’s take a look at them.

3 Best Manufacturing Inventory Management Software & Features

1. Alpha TransForm

Alpha TransForm changes how manufacturing teams handle inventory management by focusing on what matters most: getting paper processes digital fast, working reliably offline, and empowering business users to build solutions without waiting for IT support.

Unlike traditional inventory systems that require longer setup times and rely heavily on constant internet connection, Alpha TransForm lets operations managers transform existing paper inventory checklists, Gemba walks, 5S audits, and equipment inspection forms into powerful mobile apps in hours, not weeks.

This agility is critical for manufacturing leaders seeking quick wins and immediate ROI from their digital transformation investments.

Our patented offline-first technology ensures inventory apps work flawlessly even in the challenging environments common in manufacturing facilities. Workers can scan barcodes, capture timestamps, document equipment conditions with photos, collect digital signatures, and record inventory counts—all while completely disconnected from networks. Data synchronizes automatically when connectivity is restored, removing frustrations caused by lost work or incomplete records.

Key features:

- Patented offline-first mobile apps that function seamlessly without internet or cell coverage.

- Barcode and QR code scanning, GPS location capture, photo and video documentation, and digital signatures for comprehensive inventory data collection.

- Conditional logic automates workflows by displaying or hiding fields, triggering alerts, and guiding workers step-by-step—ensuring inventory inspections and counts are consistent, accurate, and completed more efficiently.

- Rapid digitization of paper forms into customizable no-code mobile apps built by business users.

- Smooth integration with existing ERP and data systems to ensure a unified inventory data source.

Alpha TransForm allows operations managers to convert paper checklists into powerful mobile apps.

Its business-user-first design permits plant managers and quality teams to build, customize, and modify inventory apps independently, significantly reducing the typical IT bottlenecks that stall digital transformation initiatives.

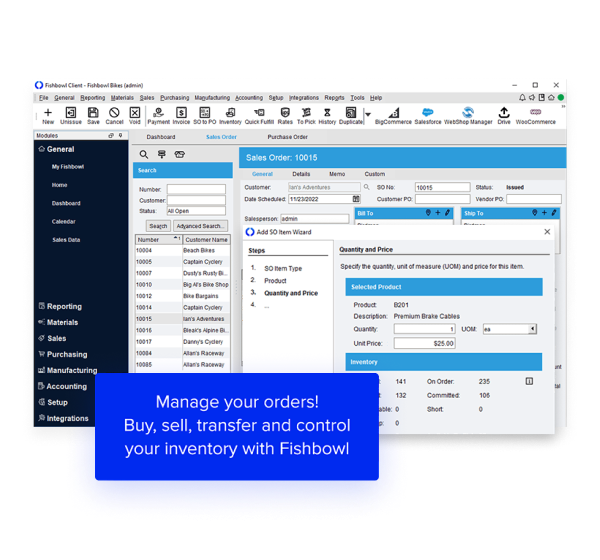

2. Fishbowl

Fishbowl serves as a solution for manufacturers requiring inventory integration with production workflows. The platform provides features for tracking raw materials, managing work orders, and handling multi-warehouse operations.

Key strengths include purchase order management, bill of materials tracking, and integration with accounting systems like QuickBooks.

Key features:

- Real-time inventory tracking with automated reorder points to control stock levels

- Bill of materials (BOM) and work order management to streamline production workflows

- Barcode scanning and cycle counting to optimize warehouse operations

- Lot and serial number tracking for regulatory compliance and traceability

- Integration with accounting software such as QuickBooks

3. Katana

Katana provides cloud-based inventory management with a user-friendly design. The platform offers manufacturing teams real-time inventory visibility and integrates with platforms such as Shopify, QuickBooks, and Xero.

Katana includes production status dashboards and supports barcode scanning for inventory counts. Its cloud-based design allows remote access and multi-location visibility for manufacturers with distributed operations.

Fishbowl is suitable for managing multi-warehouse operations.

Key features:

Key features:

- Real-time inventory tracking for raw materials and finished goods across multiple locations.

- Visual, drag-and-drop production scheduling to prioritize tasks and monitor progress efficiently.

- Sales order management integrated with eCommerce platforms to centralize order fulfillment.

- Shop floor task management that helps with assigning jobs to operators, tracks progress in real time, and gives managers visibility into workloads to keep production running smoothly.

- Seamless integration with accounting software like QuickBooks and Xero

Katana’s subscription pricing typically offers scalable tiers tailored to different business sizes, emphasizing affordability and ease of use for manufacturers, simplifying their inventory control processes.

Katana has a cloud-first design that enables remote access and multi-location visibility.

Pricing Breakdown

Each platform has a distinct pricing approach, ranging from license fees to tiered subscriptions and value-based SaaS plans. Here’s a simplified comparison:

Alpha TransForm Pricing

Alpha TransForm has a Free tier allowing up to 3 users and 35 forms per month, including offline data collection, mobile and browser access, and API integrations. The Business plan starts at $30 per user monthly, offering unlimited forms, offline support, API access, and dedicated customer success.

For larger or specialized teams, an Enterprise plan with flexible usage-based pricing, onboarding, and on-premise options is available. This model is ideal for manufacturers prioritizing rapid digitization and operational agility with minimal upfront costs.

Fishbowl Pricing

Fishbowl offers tiered pricing plans designed to scale with business size and complexity. The Essentials plan starts at $199 per month for small businesses and includes 2 users, core inventory tracking, item/SKU management, and cycle counts.

The Growth plan costs $399 per month with 5 users and adds fulfillment support, shipping tools, and AI-driven reporting. The Scale plan at $699 per month includes 10 users, advanced permission controls, forecasting, and demand planning for mid-sized businesses.

For enterprises needing full control and automation, Fishbowl also has a customizable Advanced plan with features like payment processing and audit trail reporting.

Katana Pricing

Katana has a flexible cloud pricing model starting with a Free plan that includes unlimited users and integrations, supports up to 30 SKUs, and 3 inventory locations—great for small teams or trials.

The Standard plan costs $359 per month (billed annually) and provides unlimited SKUs, 3 locations, barcode scanning, advanced insights, multicurrency support, API access, and free onboarding, ideal for growing manufacturers.

The Professional plan is $799 per month with support for up to 10 locations and adds full traceability, planning, forecasting, warehouse management, and enhanced workflow capabilities.

For large-scale companies, they also have a Professional Plus plan with unlimited locations, priority support, dedicated account management, and tailored pricing.

*Note: Pricing and/or product availability mentioned in this post are subject to change. Please check the retailer's website for current pricing and stock information before making a purchase.

Alpha Transform vs Fishbowl vs Kata: Comparison Table

|

Feature Category |

Alpha TransForm |

Fishbowl |

Katana |

|

Offline Capability |

Patented offline-first technology |

Requires internet connection |

Cloud-based only |

|

Barcode Scanning |

Barcode & QR code scanning |

Barcode scanning |

Barcode scanning support |

|

Mobile Apps |

Custom mobile apps in hours |

Limited mobile functionality |

Mobile-responsive interface |

|

No-Code Platform |

Business users build apps |

Requires IT involvement |

Standard interface only |

|

ERP Integration |

Seamless integration |

Deep ERP integration |

Limited ERP options |

|

Production Planning |

Workflow automation |

Work order management |

Visual production scheduling |

|

Multi-location Support |

GPS location capture |

Multi-warehouse operations |

Multiple inventory locations |

Which Platform Should You Choose?

Fishbowl is better suited for manufacturers with complex ERP environments. It offers deep integrations and can support large-scale operations that need robust system connections. The trade-off is a heavier upfront investment and a longer setup time.

Katana serves manufacturers and those in e-commerce who need straightforward inventory management tied into accounting or online sales platforms. Its strength lies in simplicity and affordability, though it doesn’t provide the offline reliability or process digitization that Alpha TransForm delivers.

Alpha TransForm is built for manufacturers who can’t afford downtime. Its patented offline-first technology ensures inspections, audits, and inventory data collection run smoothly even in areas with poor or no connectivity. On top of that, it digitizes the exact paper forms manufacturing plants still depend on—safety checklists, compliance reports, and equipment inspections—so teams see immediate operational improvements without heavy IT involvement.

Why Alpha TransForm is the Best Manufacturing Platform

Alpha TransForm is built specifically for the practical needs of manufacturing teams, whether on the production line, in the warehouse, or in the field. Business users, often called citizen developers, can create powerful inspection and data collection apps fast, with no coding required.

Works Anywhere

Works Anywhere

Alpha TransForm’s offline-first technology ensures apps run smoothly even in areas with poor or no connection. This is ideal for warehouses, remote sites, and factory floors. It supports photos, barcodes, GPS, signatures, timers, and more. Automatic alerts and reports can be triggered instantly as inventory checklists are completed.

Build Quickly & Scale Easily

Plant supervisors and quality teams can create and launch custom apps for tasks like 5S audits, Gemba walks, equipment inspections, and inventory checks in minutes—no waiting for IT or long rollouts. Alpha TransForm integrates seamlessly with existing tools such as Excel, SQL, and ERP systems, ensuring data flows directly into critical business processes and dashboards.

With Alpha Transform, you can create a powerful app fast, without coding.

Trusted by Industry Leaders

Manufacturers worldwide rely on Alpha TransForm to modernize workflows and reduce operational risk. Customers like Igloo have digitized manual quality control processes, saving $145,000 while improving accuracy and team productivity. Whether supporting a few users or hundreds, Alpha TransForm scales to fit your business with enterprise-level security, mobile compatibility, and flexible deployment options.

Alpha TransForm transforms production floor data collection into a competitive advantage, helping manufacturing teams work smarter, faster, and more reliably.

Frequently Asked Questions (FAQs)

What makes inventory management software suitable for manufacturing environments?

Manufacturing inventory software must handle challenging physical environments with reliable offline functionality, support barcode scanning and photo capture for documentation, and integrate with existing production systems. The best solutions work without constant internet connectivity and can be deployed rapidly to deliver quick ROI.

How quickly can manufacturing teams implement new inventory management software?

Implementation speed varies by platform. Alpha TransForm enables teams to digitize inventory processes in minutes using existing paper forms as templates. Traditional systems may require longer.

Do manufacturing inventory apps work reliably without internet connectivity?

This depends on the platform's offline capabilities. Alpha TransForm’s patented offline technology ensures full functionality without connectivity. So, workers can scan barcodes, capture photos, and complete forms with automatic syncing when networks return. Other platforms may offer limited offline features or require constant connectivity for full functionality.

What's the typical ROI timeframe for manufacturing inventory management software?

ROI depends on implementation speed and feature adoption. Alpha TransForm users typically see returns within weeks due to rapid deployment and immediate elimination of paper processes. More complex systems may take months to show full ROI as teams complete training and integrate with existing workflows. The key is choosing software that delivers value from day one.

Why do manufacturing teams choose Alpha TransForm over other inventory management platforms?

Alpha TransForm stands out by focusing on what manufacturing operations actually need: rapid digitization of paper processes, reliable offline operation in challenging environments, and the ability for business users to build solutions without IT bottlenecks. Our offline technology, manufacturing-specific features like equipment inspection forms and 5S audit tools, and proven ROI make it the practical choice for operations leaders who need results fast.

Comment