Learn to create effective equipment inspection checklists with digital templates and step-by-step guides for manufacturing, construction, and field operations today.

Learn to create effective equipment inspection checklists with digital templates and step-by-step guides for manufacturing, construction, and field operations today.

Key Takeaways

- Equipment inspections require structured checklists with clear criteria and accountability measures to maintain safety and compliance.

- Paper-based inspection processes create delays, documentation gaps, and data loss that slow corrective actions and increase compliance risks.

- Effective digital equipment inspection checklists include photo capture, GPS tracking, barcode scanning, and offline functionality for reliable field operations.

- Mobile inspection apps enable real-time data collection, instant reporting, and automated workflows that accelerate maintenance cycles.

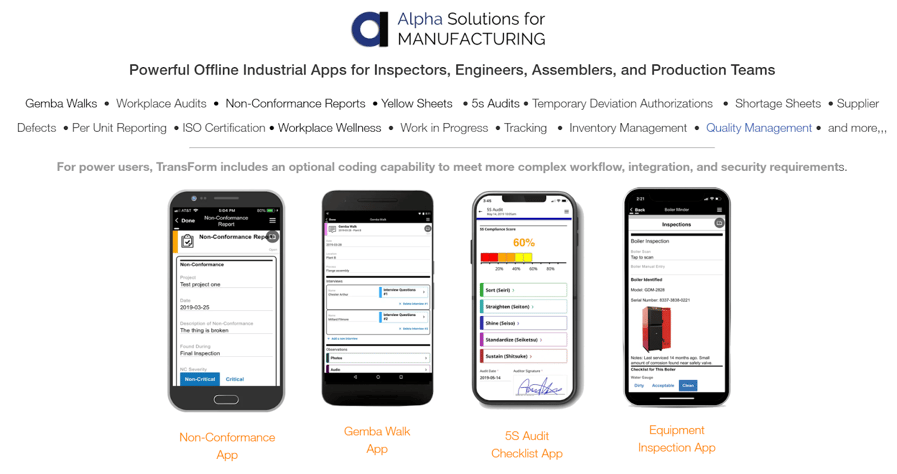

- Alpha TransForm's easily customizable Equipment Inspection App is an example of how digital templates can optimize field operations.

Why Equipment Inspections Drive Operational Success

Equipment inspections form the backbone of safe, compliant operations across manufacturing, construction, and healthcare. Modern businesses need equipment inspection processes that capture accurate data, work in challenging environments, and deliver immediate insights for faster decision-making.

Mission-critical equipment, like forklifts and conveyor systems, needs regular inspection to maintain regulatory compliance and prevent costly downtime. Equipment failures halt production, create safety hazards, and incur repair costs that can affect budgets.

Regular equipment audits also help businesses meet OSHA requirements and build predictable maintenance schedules. When inspections are thorough and timely, they catch small issues before they become major problems. A loose bolt identified during routine inspection costs dollars to fix. The same bolt causing equipment failure during peak production can cost thousands in downtime and repairs.

Traditional paper inspections, however, often fail to deliver on these promises. Forms get lost between shifts, handwritten notes become illegible, and critical photos taken separately on phones never make it into official records. By the time inspection data reaches decision-makers, conditions may have already changed, and opportunities for preventive action are lost.

Elements of Effective Equipment Inspection Checklists

Building a comprehensive equipment inspection checklist requires careful consideration of several parts that ensure thorough, consistent evaluations. Each element serves a specific purpose in creating reliable documentation and driving actionable outcomes. Some of these include:

Equipment Identification

Start every inspection checklist with clear equipment identification. Include asset tags, serial numbers, model information, and location details. This seems basic, but consistent equipment identification prevents confusion and ensures inspection history follows the right assets. Digital templates can use barcode scanning to automatically populate equipment details, reducing errors and speeding up the identification process.

Pre-Inspection Safety Checks

Before examining any equipment, inspectors need to verify safe operating conditions. This includes confirming that lockout/tagout procedures are followed, personal protective equipment is properly worn, and the inspection area is clear of hazards. Safety checks should be completed before proceeding with operational inspections.

Operational Assessment

Operational Assessment

Structure equipment inspections to follow sequences. For mechanical equipment, this might mean starting with visual inspection, then moving through lubrication points, electrical connections, safety systems, and performance indicators. Consistency like this helps inspectors develop efficient routines that make sure nothing gets overlooked.

Clear Pass/Fail Criteria

Eliminate ambiguity by defining specific criteria for each inspection item. Instead of asking whether something "looks good," provide measurable standards like belt tension specifications, acceptable oil levels, or temperature ranges.

Safety checks should be completed before proceeding with operational inspections.

How to Create an Equipment Inspection Checklist

Developing an effective equipment inspection checklist requires an approach that considers unique operational situations and regulatory requirements. Following a structured process ensures your checklists capture critical information while remaining practical. Below are some steps to creating an effective checklist:

1. Define Scope & Equipment Categories

Begin by cataloging the equipment requiring regular inspection within your facility. Group similar equipment types together to create standardized checklists that can be applied consistently. Consider regulatory requirements, manufacturer recommendations, and operational criticality when determining the frequency and depth of inspections.

2. Structure Inspection Sequences

Organize checklist items in the order inspectors will encounter them during their walkthrough. Start with safety verification, move through visual inspections, then progress to operational tests and performance measurements.

3. Define Measurement & Documentation Requirements

Specify exactly what data needs to be captured for each inspection item. This includes numerical measurements (pressures, temperatures, vibration levels), visual evidence (photos of wear patterns, leak locations), and qualitative assessments using standardized criteria. Clear documentation requirements ensure inspections provide actionable data for maintenance decisions.

4. Establish Sign-off Procedures

Define who performs the inspection, who reviews results, and who authorizes any required corrective actions. Digital signatures with timestamps create auditable records that demonstrate compliance and support accountability throughout the inspection process.

5. Create Follow-up & Corrective Action Workflows

Plan how inspection findings will trigger maintenance actions, parts ordering, or additional technical assessments. The best inspection checklists identify problems and initiate structured responses that ensure issues get resolved promptly.

A Digital Template That Streamlines Equipment Inspections

Alpha TransForm’s Equipment Inspection App is an example of how digital templates can optimize field operations. This pre-built solution helps make equipment evaluation a streamlined workflow that delivers immediate value. It is easily customizable, optimized for one-handed data entry. The app can look up equipment model information, capture torque or other measurements, and perform calculations with a click.

Key features:

- Maintain visual consistency with company logos and color schemes to ensure inspection forms appear professional, align with brand standards, and are easily recognizable in the field by crews.

- Automatically record location and time data to build reliable audit trails, proving exactly when and where inspections were performed.

- Fast reference and form launch through color-based visual organization helps inspectors quickly find the right checklist, reducing setup time and errors.

- One Tap Pass/Fail definitions speed up the inspection process, ensuring issues are flagged instantly and consistently.

- Built-in stopwatches and alarms track inspection duration and equipment performance timing, adding precision to testing and maintenance routines.

- Fast one-handed entry of measurements optimized for field conditions allows workers to capture torque, readings, and notes efficiently while handling tools or equipment.

Once inspections are complete, digital signatures and timestamps can be used to create tamper-proof records.

Real-World Equipment Inspection Examples

Manufacturing Conveyor Belt Inspection

Daily conveyor inspections focus on belt tension, roller alignment, emergency stops, and lubrication points. Digital checklists can capture belt wear photos, record tensioning measurements, and verify safety system functionality. GPS coordinates confirm inspections occurred at the correct equipment locations, while automatic timestamps create audit trails for regulatory compliance.

Construction Crane Safety Inspection

Pre-shift crane inspections require verification of operator credentials, structural integrity checks, hydraulic system performance, and load testing checks. Mobile templates can capture operator certifications through photo scanning, record hydraulic pressure readings, and document structural inspection photos with location data.

How Alpha TransForm Improves Operational Efficiency

Alpha TransForm improves the efficiency of equipment inspections by replacing paper-based processes with fast, reliable digital workflows that deliver immediate value. Operations leaders trust our platform because it eliminates many of the issues that arise from paper-based forms, shortens reporting delays, and provides instant access to results that accelerate decision-making.

It has a patented offline-first architecture that ensures inspections run seamlessly even without WiFi or cell service, guaranteeing that critical safety and compliance checks are completed and recorded every time.

Supervisors and managers gain the ability to digitize inspections on their own, rapidly expand to safety checklists, 5S audits, Gemba walks, and maintenance workflows, as well as demonstrate ROI within days. Inspection data captured in Alpha TransForm flows directly into existing ERP, quality, and maintenance systems, automatically triggering work orders, compliance reports, and alerts.

We are trusted by manufacturers who use our platform, and some, like Igloo, have achieved a reduction in quality control costs by over $145,000 while improving accuracy, efficiency, and compliance. From equipment inspections to broader operational workflows, Alpha TransForm enables manufacturers to standardize processes, improve visibility, and scale seamlessly, all without added IT overhead.

Operations teams can build and deploy custom inspection apps in less than 30 minutes without IT involvement.

Are you ready to see how Alpha TransForm can optimize your operational efficiency?

Frequently Asked Questions (FAQs)

What should be included in a comprehensive equipment inspection checklist?

A complete equipment inspection checklist includes equipment identification details, pre-inspection safety verification, component assessments, measurement requirements, visual evidence, clear pass/fail criteria, and accountability measures with digital signatures and timestamps.

How often should equipment inspections be conducted?

Inspection frequency depends on equipment, regulatory requirements, and manufacturer recommendations. Critical safety equipment may require daily inspections, while standard operational equipment might be inspected weekly or monthly. High-use equipment in harsh environments typically needs more frequent inspection than equipment in controlled conditions.

What documentation is required for compliance with safety regulations?

Regulatory compliance requires detailed records including inspection dates, inspector identification, specific findings, corrective actions taken, and verification signatures. Digital templates automatically capture timestamps and signatures that satisfy OSHA requirements.

How can digital templates improve equipment inspection accuracy?

Digital templates eliminate transcription errors, provide clear pass/fail criteria, capture photographic evidence automatically, and use conditional logic to ensure all relevant items are inspected. Built-in validation prevents incomplete submissions while automatic data population reduces manual entry errors that commonly occur with paper forms.

How does Alpha TransForm help operations teams digitize equipment inspections?

Alpha TransForm enables operations leaders to transform paper inspection forms into mobile apps in minutes without IT involvement. The platform's offline-first architecture works reliably in challenging industrial environments, while built-in integrations ensure inspection data flows directly into existing maintenance and compliance systems for immediate action.

Comment