Discover how to conduct effective Gemba Walks in your warehouse with practical checklists. Learn how Alpha TransForm digitizes your audits for better results.

Key Takeaways

- Gemba Walks help warehouse managers identify inefficiencies, safety hazards, and process bottlenecks by observing operations on the floor where the work is performed.

- Ready-to-use downloadable templates streamline implementation, allowing warehouses to start conducting structured Gemba Walks immediately without building checklists from scratch.

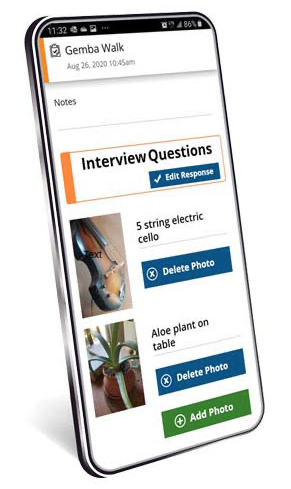

- Alpha TransForm’s pre-built Gemba Walk App streamlines Gemba walk-throughs by capturing manager notes, photos, measurements, and other observations, and you can quickly tailor the app with custom questions to fit your specific Gemba process.

What Is a Gemba Walk & Why Warehouses Need Them

A Gemba Walk is when managers and supervisors leave their desks and spend time on the warehouse floor observing operations, talking with workers, and identifying opportunities for improvement.

This practice has become essential for modern warehouse management. Unlike reviewing reports or watching security footage, Gemba Walks give you unfiltered insight into daily operations. You see the workarounds employees create, the equipment that's starting to fail, the bottlenecks that metrics don't capture, and the safety risks hiding in plain sight.

Workers notice when leadership shows up and asks questions. That engagement builds trust, surfaces ideas you'd never hear in formal meetings, and creates a culture where continuous improvement becomes everyone's responsibility.

Your Warehouse Needs a Structured Gemba Walk Checklist

Walking the floor without a plan turns into casual observation. You might spot obvious problems, but you'll miss patterns and overlook entire areas. A structured Gemba Walk checklist ensures you systematically cover every critical zone and capture findings that drive action.

Your checklist creates a repeatable process across different managers, builds accountability, and creates a historical record of conditions over time. Without one, observations get forgotten, action items fall through the cracks, and follow-up becomes hit-or-miss.

Essential Elements of a Warehouse Gemba Walk Checklist

Your checklist needs to cover the full scope of warehouse operations:

- Safety & Compliance: Check that personal protective equipment is worn correctly, emergency exits remain clear and marked, spill kits are accessible, fire extinguishers are current, lighting is adequate, and walkways are free of trip hazards.

Alpha TransForm's offline-first architecture ensures reliability during Gemba walks,

floor audits, and equipment inspections in areas with poor connectivity.

- Equipment Condition: Inspect forklifts, pallet jacks, conveyor systems, dock plates, packaging equipment, and racking for damage or wear. Document equipment that's overdue for maintenance or showing signs of failure.

- Process Flow & Efficiency: Observe receiving, putaway, picking, packing, and shipping operations. Look for unnecessary motion, waiting time, confusing layouts, or redundant steps.

- Inventory Management: Verify that items are stored in the correct locations, that labels are legible and accurate, that stock rotation follows FIFO or FEFO rules, and that damaged goods are segregated.

- Work Methods & Training: Watch how employees perform tasks. Get answers to questions, like are they following standard procedures? Using proper lifting techniques? Do they have the tools they need?

- Housekeeping & Organization: Rate the cleanliness of work areas, condition of floors, organization of tools and supplies, and whether 5S principles are being maintained.

Ready-to-Use Gemba Walk Templates for Warehouses

You can download these templates directly from the sources and use them immediately for your Gemba walk observations and continuous improvement initiatives.

NHS Wales Improvement Cymru Academy - Gemba Walk Toolkit Guide

The NHS Wales Improvement Cymru Academy Gemba Walk Toolkit Guide provides a comprehensive resource covering what Gemba is, the rationale for conducting Gemba walks, three essential elements (Go and See, Ask Why, Respect People), and seven helpful steps.

The guide includes a pre-Gemba walk checklist for planning theme selection, team preparation, and observation recording. Use this toolkit when you're in a warehouse implementing Lean management principles, and need structured guidance that emphasizes respect for people and collaborative improvement.

Alpha TransForm’s Pre-Built Gemba Walk App

Alpha TransForm’s pre-built Gemba Walk App gives teams a ready-to-use digital tool for conducting structured walk-throughs on the warehouse floor. The app is included with an Alpha TransForm account, so you can start using it right away without building anything from scratch.

It captures notes, photos, measurements, timestamps, and GPS data, and it works offline to ensure observations are recorded even in areas with poor connectivity. You can also customize the questions, workflow steps, and data fields to match your warehouse’s specific Gemba Walk process, making it a practical option for Lean teams that need accurate, real-time insights during daily or weekly tours.

How to Conduct an Effective Gemba Walk

Before the Walk

Decide what you want to focus on: safety improvements, process bottlenecks, or equipment reliability. Schedule walks during different shifts to see varying conditions, and bring the right people: a supervisor who knows the area and a frontline worker who does the tasks daily.

During the Walk

Move slowly and deliberately. Ask open-ended questions: "What's the most frustrating part of this process?" "What would make this easier?" Listen more than you talk. Take photos of conditions, not just problems. Use your checklist to stay on track.

After the Walk

Review findings immediately while observations are fresh. Prioritize issues by severity and impact. Assign ownership for each action item with clear deadlines, and share results with the team.

The Problem with Paper Checklists & PDF Templates

Most warehouses download PDF templates, print them on clipboards, and walk the floor with a pen in hand. Supervisors scribble notes, snap photos on their phone, then return to their desk to type everything into spreadsheets or emails.

This creates multiple problems. Photos and notes live in different places. Handwriting is illegible. PDFs get filed away without action. There's no easy way to track whether corrective actions happened, and analyzing trends across dozens of printed forms requires manual data entry.

Paper checklists also limit who can participate and add days between observation and action. By the time findings get documented and distributed, conditions may have already changed or worsened.

And when you are using digital tools, warehouses present unique challenges: metal structures block cell signals, Wi-Fi coverage is spotty in loading bays, and connectivity drops in cold storage areas. That's why offline-first digital solutions are essential—not optional—for reliable Gemba Walk documentation.

Paper checklists create disconnected data, with photos and notes stored in different places,

handwriting becoming illegible, and analyzing trends requiring manual data entry.

Why Choose Alpha TransForm for Warehouse Gemba Walks

Alpha TransForm’s pre-built Gemba Walk App is ready to use as soon as you log in to Alpha Software, giving warehouses an immediate digital checklist that works even in areas with spotty or nonexistent internet.

Your team can complete inspections offline, and the data syncs automatically once connectivity returns, preventing lost work in extensive facilities or multi-building sites. The app includes built-in features like photo capture, barcode scanning, GPS tagging, digital signatures, and conditional logic that adapts questions based on what’s being inspected.

You can easily customize the checklist by adding or removing fields to match your unique Gemba Walk process, and dashboards give managers real-time visibility into completion rates, recurring issues, and overdue corrective actions.

The same platform also supports 5S audits, equipment inspections, safety walkthroughs, inventory counts, dock checks, and other warehouse workflows.

In fact, one of our clients, Igloo, cut quality control expenses by $145,000 with inspection apps built on Alpha TransForm, while improving accuracy and team productivity. With direct integration into their maintenance and Enterprise Resource Planning (ERP) systems, inspection data flows seamlessly into daily operations, automatically triggering work orders and compliance documentation with no manual input.

Ready to replace paper Gemba Walks with a digital system that gives you clearer insights and stronger operational control?

Alpha TransForm's Gemba Walk App is built for offline environments,

allowing teams to complete checklists without connectivity and automatically syncing data when back in range.

Frequently Asked Questions (FAQs)

What should be included in a warehouse Gemba Walk checklist?

A comprehensive warehouse Gemba Walk checklist should cover safety and compliance checks, equipment condition assessments, process flow observations, inventory management practices, employee work methods, and housekeeping standards.

Each section needs specific items with space for ratings, photos, and corrective action notes. The checklist should be tailored to your facility's unique layout, equipment, and operational priorities rather than using a generic template without customization.

How often should warehouses conduct Gemba Walks?

The frequency depends on your warehouse size, complexity, and current performance. Most operations benefit from weekly walks covering different zones or shifts.

High-volume facilities or those with active improvement initiatives might walk daily, focusing on specific problem areas. Smaller warehouses can conduct thorough monthly walks.

Can Gemba Walks be done digitally, or do they require paper?

Gemba Walks work better with digital tools than paper checklists. Mobile apps capture photos directly with observations, work offline in areas without connectivity, automatically timestamp and GPS-tag findings, and instantly share results with relevant teams.

Digital eliminates the transcription step, where paper notes are converted into reports, reducing errors and delays.

What's the difference between a Gemba Walk & a safety audit?

A Gemba Walk is broader than a safety audit. While safety is one component, Gemba Walks also examine process efficiency, quality practices, equipment condition, inventory accuracy, and employee engagement. The goal is continuous improvement across all dimensions of warehouse operations.

Safety audits have a narrower compliance-focused scope with pass/fail criteria. Gemba Walks encourage observation and conversation rather than just checking boxes, though they absolutely should identify and document safety issues when found.

How does Alpha TransForm improve Gemba Walk effectiveness?

Alpha TransForm includes a pre-built Gemba Walk App that teams can use immediately, giving warehouses an offline-capable mobile checklist that captures photos, barcodes, GPS data, and signatures on the spot. The app syncs automatically when connectivity returns, uses conditional logic to adapt questions based on what’s being inspected, and can be customized to fit your exact Gemba process.

The no-code app builder also sends alerts for critical findings and generates automated reports that highlight trends across shifts, areas, and repeated walk-throughs. It’s designed for operational teams, requires no coding, and removes IT bottlenecks so you can optimize your Gemba Walks without delay.

*Note: Pricing and/or product availability mentioned in this post are subject to change. Please check the retailer's website for current pricing and stock information before making a purchase.

Comment