Discover 5S audit checklist templates with step-by-step instructions for manufacturing. Get digital templates for Sort, Set, Shine, Standardize, Sustain today.

Discover 5S audit checklist templates with step-by-step instructions for manufacturing. Get digital templates for Sort, Set, Shine, Standardize, Sustain today.

Key Takeaways

- 5S audits require structured checklists covering Sort, Set in Order, Shine, Standardize, and Sustain to maintain workplace organization and safety standards.

- Paper-based 5S audits create delays, documentation gaps, and compliance risks that slow corrective actions and reduce accountability.

- Effective 5S audits follow proven methodologies with clear scoring systems, evidence requirements, and follow-up protocols that drive continuous improvement in manufacturing facilities.

- Digital 5S audit templates enable real-time data capture and instant reporting that accelerate improvement cycles.

- Alpha TransForm’s 5S audit app is a customizable offline-first app that helps you score each audit and keeps progress measurable over time.

What Are 5S Audits & Why Are They Important?

In manufacturing, efficiency and safety determine profitability. 5S audits are structured evaluations that measure how well a workplace follows the five principles of lean manufacturing: Sort, Set in Order, Shine, Standardize, and Sustain. Together, these practices ensure tools are organized, work areas are clean, and procedures are consistent, creating a safer and more efficient environment.

A 5S audit goes far beyond keeping a factory floor tidy. It reduces wasted time and motion, prevents accidents, and helps establish predictable workflows. Regular audits also support ISO compliance, prepare facilities for regulatory inspections, and build a culture where employees take ownership of their workspace.

The Hidden Costs of Paper-Based 5S Audits

Traditional 5S audits still lean heavily on clipboards, paper forms, and manual data entry. Auditors walk the floor with printed checklists, jot down notes by hand, snap photos separately on their phones, and then hope everything makes it back to the office in one piece. By the time information is organized, delays have already crept in, undermining the whole idea of continuous improvement.

Paper-based audits come with many headaches, such as messy handwriting, missing signatures, and half-completed forms that leave compliance gaps. If a form gets damaged, misplaced, or left behind on the shop floor, the audit cycle has to be repeated, consuming valuable time and resources. Even when everything goes right, managers often wait days or even weeks for results to be consolidated, which means site conditions may have already shifted and opportunities to improve are long gone.

With paper records, tracking performance trends across shifts, departments, or multiple facilities is prone to errors. Compiling scores by hand is slow, and without timestamps or photo evidence, it’s difficult to hold people accountable or act with urgency. In the end, corrective actions lose their impact, and the audit becomes more of a formality than a tool for real improvement.

Essential Components of an Effective 5S Audit Checklist

Sort

Sort

Workstations should be free of clutter, with clear procedures for moving out unused materials and a designated spot for anything temporarily stored. Auditors typically check for red-tagged items, piles of excess inventory, or tools that haven’t been touched in weeks. The goal is simple: eliminate what doesn’t add value so workers can focus on what matters.

Set in Order

Once the clutter is gone, the next focus is organization. Set in Order is all about making tools and materials easy to find, use, and return. During audits, supervisors look for proper labeling, designated storage locations, and visual cues that guide workers to the right spot every time. Shadow boards, color coding, and floor markings are common tools that keep everything in its place. An effective audit confirms these systems aren’t just installed but are actually being used.

The first step in any 5S audit is making sure only what’s needed is on the shop floor.

Shine

Shine goes deeper than keeping the workplace tidy. It’s about maintaining equipment and ensuring small issues don’t grow into big problems. Auditors look for signs like oil leaks, debris buildup, or delayed maintenance tasks that could affect safety or quality.

Standardize

The fourth pillar makes sure improvements stick. Standardization requires that processes be documented and applied consistently across shifts. Auditors review standard operating procedures, training records, and evidence that best practices are followed day in and day out. Without this consistency, early gains fade quickly, so this stage of the audit is critical for long-term results.

Sustain

The final piece is sustaining progress over time. Auditors check whether teams are holding regular audits, collecting employee feedback, and driving continuous improvement initiatives.

Step-by-Step Instructions for Conducting 5S Audits

A strong 5S audit follows a structured process that gives you an honest snapshot of how the workplace is really operating. Start by scheduling audits during normal working hours so conditions reflect day-to-day reality.

Next, log the basics: date, time, location, auditor name, and shift. These details may seem small, but they’re critical for spotting trends and holding teams accountable. Before you begin, review the previous audit to confirm that corrective actions were completed and check if any issues have resurfaced.

As you move through the floor, evaluate one 5S pillar at a time—Sort, Set in Order, Shine, Standardize, Sustain. Using a simple scoring system, like a 1–5 scale or pass/fail, keeps evaluations consistent and objective.

How you document findings makes a big difference. Vague notes like “area needs cleaning” don’t drive change. Clear, specific observations such as “Oil buildup under Machine #3 requires daily cleaning” make it easy to assign responsibility and take immediate action.

Finally, wrap up by assigning owners, setting deadlines, and scheduling follow-ups to confirm improvements are sustained. Share results quickly with supervisors and operators so momentum isn’t lost.

A digital 5S audit template solves these problems by streamlining the entire process. With a mobile app, you log scores, assign tasks, and share results instantly. This makes audits faster, more accurate, and easier to act on, making them a more effective tool for continuous improvement.

Digital Templates That Optimize 5S Audits

Paper checklists slow down audits, create errors, and make it harder to act on findings. Digital templates designed for manufacturing environments solve this by capturing more accurate data, reducing administrative work, and making audit results easier to track over time.

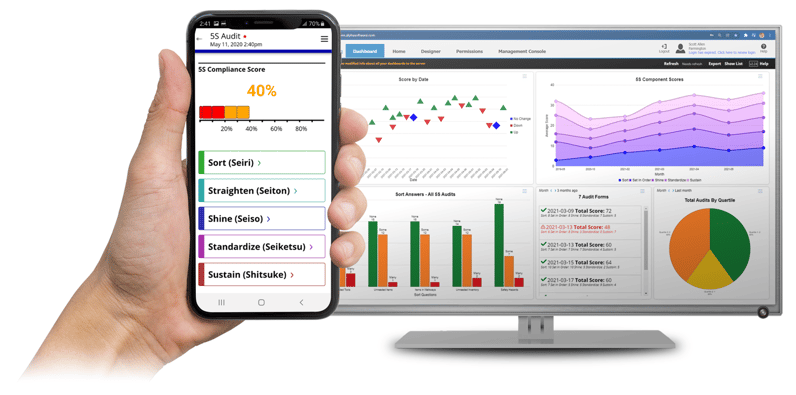

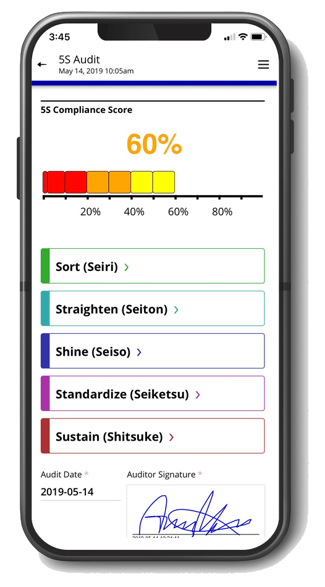

An example of a digital template that does just this is Alpha Software’s 5S Audit App, which takes these benefits further by giving manufacturers a practical, mobile tool built for real shop-floor conditions.

The challenge is that paper checklists slow everything down. They’re easy to lose, hard to analyze, and often delay corrective action.

It works as a customizable offline-first app that helps you score each audit and keeps progress measurable over time. It ensures accountability through signatures and timestamps, while managers gain traceable records they can analyze through visual dashboards or exported reports.

Key features:

- Run audits anywhere on the facility floor, even while offline.

- Capture signatures and timestamps to create verifiable records for compliance and long-term analysis.

- Customize the audit template to match your specific processes, equipment, and facility standards.

- Export results as PDFs, Excel files, or view them on dashboards for quick analysis and follow-up.

Digital templates designed for manufacturing environments make audit results easier to track over time.

Alpha TransForm Helps Deliver Manufacturing Excellence

Alpha TransForm changes how manufacturing teams approach 5S audits by putting powerful digital tools directly into the hands of operations leaders and business users. We enable plant supervisors and quality managers to build custom 5S audit apps in under 30 minutes using our no-code platform.

We understand the importance of reliability in manufacturing processes and our offline-first 5S app ensures audits continue uninterrupted in warehouses, production floors, and remote facilities where connectivity is unreliable.

Manufacturing teams can deploy our Alpha TransForm 5S audit app instantly across multiple facilities without waiting for IT resources or complex integrations. The platform connects with existing ERP systems, ensuring audit data flows seamlessly into core business systems.

Operations leaders gain real-time visibility into compliance trends through interactive dashboards that highlight areas requiring attention and track improvement progress over time.

Manufacturing companies like Igloo have reduced quality control costs by $145,000 while increasing accuracy and team efficiency using Alpha TransForm-powered applications. These results demonstrate how digitizing manufacturing processes creates measurable operational improvements.

From equipment inspection to Gemba walk and toolbox talk apps, Alpha TransForm scales with manufacturing needs while maintaining the simplicity that keeps business users productive. Whether supporting five users or five hundred, our platform delivers consistent performance without requiring additional IT overhead.

Ready to drive measurable manufacturing improvements?

Manufacturing teams can deploy Alpha TransForm 5S audit apps instantly across multiple facilities.

| Try Alpha TransForm Now → |

Frequently Asked Questions (FAQs)

What should be included in a comprehensive 5S audit checklist?

A full checklist covers all five pillars: Sort, Set in Order, Shine, Standardize, and Sustain, with clear criteria, scoring, and space for photos and corrective actions.

How often should manufacturing facilities conduct 5S audits?

Conduct general-area audits monthly and critical-zone audits weekly. New implementations may require more frequent checks initially, while mature areas may move to quarterly audits.

What documentation is required for 5S audit compliance?

Include date/time, auditor and location details, pillar scores, corrective actions (with owners and deadlines), follow-up verification, signatures, and timestamps. Digital templates like Alpha TransForm’s 5S audit app improve traceability and prevent data loss or illegibility.

How can manufacturing teams improve employee engagement in 5S audits?

Make audits participatory by involving front-line workers and rotating roles across shifts. Share results openly, offer training, encourage improvement suggestions, and publicly recognize strong performance to foster engagement.

Comment