Low-code and no-code software can bring incredible value to small manufacturers. Digitizing paper forms, automating manual processes and bringing data to mobile devices can help small businesses gain a competitive advantage. Here's what you need to know about manufacturing software for SMBs.

Manufacturers have generally been slow to digitally transform themselves and get to what’s called Industry 4.0, powered by IoT, big-data analytics, smart factories and other technologies. There are many reasons for that, including the shortage of available digital talent, notably programmers and software engineers.

Manufacturers have generally been slow to digitally transform themselves and get to what’s called Industry 4.0, powered by IoT, big-data analytics, smart factories and other technologies. There are many reasons for that, including the shortage of available digital talent, notably programmers and software engineers.

There’s a solution close at hand: low-code/no-code development platforms, which allow people who cannot code to write powerful applications. But some manufacturers have been leery of the platforms, because of pervasive myths about them.

Belief in these myths is holding back manufacturers from reaping the benefits of Industry 4.0. We're calling out 5 of these myths and setting the record straight. Some of these ideas were covered in the article, 6 Misconceptions About No-Code & Low-Code in Manufacturing.

Manufacturing Software Myth #1: No-Code Can Only Write Simple Apps

Manufacturing Software Myth #1: No-Code Can Only Write Simple Apps

The article attacks this one head-on, noting: “The greatest misconception about the no-code revolution is that no-code platforms can only produce simple apps. This myth stems from the impression that robust, functional manufacturing applications can only be built by those with hard-won coding skills. It likely has its roots in the MES era, when manufacturing software was designed for IT, not front-line engineers, and minor changes took a significant effort to scope, code, and push. It also couldn’t be further from the truth.”

In fact, Forbes reports, “No-code platforms have become extremely sophisticated and support rich functionality in apps. It is now possible to build most end-to-end enterprise applications on a no-code platform.”

Manufacturing Software Myth #2: No-Code Hurts IT

This myth also couldn’t be further from the truth. No-code can be IT’s best friend, by allowing business users to write useful applications, freeing IT for higher-level tasks. Everybody wins, especially the manufacturer.

Manufacturing Software Myth #3: No-Code Isn’t Scalable

Manufacturing Software Myth #3: No-Code Isn’t Scalable

The article notes: “No-code apps, in many cases, scale in manufacturing better than their hard-coded counterparts precisely because they don’t require someone to manually edit code to accommodate expanded usage and use-cases. They’re easier to design and deploy on multiple lines, in multiple factories, and they allow for small incremental updates sensitive to local conditions.”

Manufacturing Software Myth #4: No-Code Leads to Security Holes

The article debunks this one, noting, “No-code applications are completely safe. And manufacturers without cyber security expertise [who use them] are not at risk of exposing critical infrastructure or data to attacks.”

A TechTarget article backs that up, saying, no-code “addresses security problems associated with shadow IT and third-party apps through transparency, resource sharing and monitoring among citizen developers and IT professionals.”

Manufacturing Software Myth #5: No-Code Is a Fad

No-code is far from a fad – it’s the wave of the future. Gartner says that a full eighty percent of technology products and services will be built by non-technology professional' staff by 2024, thanks to no-code/low-code tools.

The Time to Go Paperless is Now

Digital transformation is no longer a nice to have; it is now a requirement for manufacturing organizations to succeed in this digital era amid labor and supplier shortages. Low-code platforms enable manufacturers to swiftly and cost-effectively adopt new technologies, often with little or no IT resources, in a scalable and cost-effective manner.

Small manufacturers should use low-code/no-code platforms to dramatically improve their production planning and manufacturing operations. This innovative business manufacturing software can help even small or medium sized companies accomplish a lot with small investment and without drawing on IT resources. Manufacturing companies can build mobile apps to help with job costing, production scheduling, production management, supply chain management, quality control, inventory control, and more.

Manufacturing Software to Help Small Businesses Companies Improve Business Operations

Intelligent mobile apps are a great step towards Industry 4.0 for small business manufacturers. By adopting quality management software to digitize paper forms, small manufacturers are realizing incredible time cost savings.

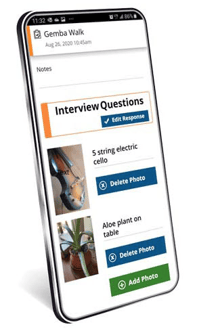

Alpha Software helps resource-constrained manufacturers digitally transform their businesses and begin to leverage IoT, analytics, AI, and more. Alpha Software helps quality, inventory or production teams collect better data by utilizing the latest mobile device features (photos, GPS, time/date stamping, bar code scanning, voice recording, etc.) for fast, accurate data capture on the manufacturing floor or in the warehouse. Built-in dashboards and powerful analytics drive faster time-to-insight. Alpha Software customers benefit from free manufacturing app templates, like the Gemba Walk template, 5S Audit template, and Non-conformance report template.

Book a meeting with us to discuss how we can help build the right solution for you.

After the call, you'll have free access to the templates.

Comment