If you’re looking to bring your factory into the future, the first thing you should consider is updating your modern manufacturing execution system (MES) to join the digital, everything-is-connected world. Doing that can reduce costs, increase efficiency, cut defects, improve output, and increase a manufacturer’s bottom line.

If you’re looking to bring your factory into the future, the first thing you should consider is updating your modern manufacturing execution system (MES) to join the digital, everything-is-connected world. Doing that can reduce costs, increase efficiency, cut defects, improve output, and increase a manufacturer’s bottom line.

The article “Manufacturing execution systems now key in digitized world” underscores how vital these systems are for moving companies toward Manufacturing 4.0, or Smart Manufacturing..

The author notes MES has been around for quite some time, but it was mired in old technology. Historically, plant networks that connect an MES system to equipment and controllers ran on ethernet, which was effective in its time, but limited MES’ connectivity and capabilities. Notably, it was difficult to connect an MES system to the ERP systems that many enterprises use.

But because ethernet technology is similar to internet protocol, it’s not difficult to connect MES systems to enterprise systems like ERP, and to the new generation of IoT devices used on factory floors. The article notes: “The formerly isolated world of plant-floor MES is now readily connectable to ERP and the internet. Manufacturing execution systems are evolving to take advantage of increased visibility and the proliferation of smart, connected Internet of Things (IoT) devices to improve process control, provide early detection of changing conditions, monitor equipment for predictive and preventive maintenance, and more.”

Manufacturing execution systems are designed for scheduling and dispatching, quality management and data collection, and when they are updated to take advantage of the latest technologies like IoT, they’re far more effective than in the past, the article notes. For example, an MES system can now gather and act on data in real time, which offers tremendous benefits. The article points out “If a transaction makes it into the system in a few hours or by the end of the shift, that's good enough for the general ledger, but not nearly good enough for plant-floor data and controls.”

MESA International, the preeminent MES system association, notes that using modern MES systems can help “bring about a revolution in manufacturing business strategy, turning traditional factories from cost centers into profitable innovation centers.”

Why Do Manufacturing Execution Systems Matter?

In addition to ushering your plant into the digital age, manufacturing execution systems can have financial and operational benefits that can transform your plant.

Here are three key MES benefits:

Digitize the Enterprise

When you adopt an MES system, you say goodbye to traditional paperwork notation, which eliinles likelihood of errors and inconsistencies. This data can then be aggregated, allowing you to identify areas for improvement and other data points that can help you hone your business.

Reduce Waste

With an MES system, you can analyze production lines in real-time, enabling you to see when and wear waste occurs. Armed with this information you can redirect leftover material or recalibrate processes.

Reduce Costs

Overtime, investment in an MES system allows you to cut costs in all verticals of your business. With more visibility into every facet of manufacturing, you can identify areas for process improvement, streamlining the how as you cut costs along the way.

How Can Manufacturing Execution Systems Make Work Easier?

While we’ve explored the business benefits of an MES system, let’s unpack how manufacturing execution systems make your employees’ day-to-day lives easier.

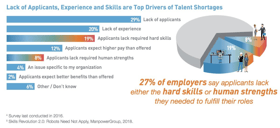

As we continue to impact staffing shortages across all industries, it’s vital that you can differentiate your place of work to potential employees.

Here’s how an MES system enables you to do just that.

Realistic Production Schedules

You can’t ask your employees to complete jobs with unattainable benchmarks. With an MES system, you gain a complete, real-time view of your supply chain, schedules, and project completion to help you build better schedules for your people.

Improved Processes

No one likes to do the same job multiple times. With an MES system, you have a view of any and all duplicities and inconsistencies in workflow. With this, you can optimize processes to make them as painless as possible for your employees.

Read Why Industry 4.0 Will be Powered By Mobile

The Best Manufacturing Solutions for the Digital Era

To leverage or augment their MES and continue to take the production floor digital, manufacturers need flexible software solutions that collect accurate data and deliver powerful analysis. Alpha Software helps manufacturers digitally transform their businesses with powerful manufacturing apps with built-in analytics. The company develops solutions that utilize the latest mobile device features (camera, GPS, digital signatures, bar code scanning, time/data stamping, etc.) for fast, accurate data collection. Once captured, data can immediately be shared or analyzed using dashboards powered by a built-in analytics engine. The solution can also tie into your corporate systems to power daily workflows.

Book a meeting with us. We'll build a solution to meet your challenge or customize one of our pre-built solutions for your needs.

|

||||||||||||||||||||||||

Comment