A Non-Conformance Report (NCR) is used to identify products, parts, or work jobs with defects that do not conform to required specifications. NCRs are critical to maintaining high quality standards for products, workmanship, safety and vendors.

Non-Conformance Reports (NCRs) are used to track and maintain quality standards at manufacturing and construction companies. They can also be used at utility and energy companies if readings are out of spec.

NCRs can also be used in virtual any industry to track quality or service issues.

NCRs allow companies to clearly identify issues with quality. An NCR report documents the details of why a part or job failed to meet quality standards, details what is needed to fix the problem, and determine a resolution or remediation. Having a strict quality process with detailed NCR reports that can be tracked and reported, allow companies to see if production is improving or decreasing and realize key trends or repeated problems with production.

Inspectors, site inspectors, quality engineers, line managers, test technicians, project managers and supervisors typically fill out non-conformance reports.

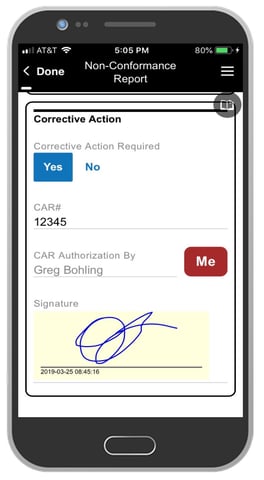

Often remediation or corrective action activities are part of an NCR. They can be tracked on a separate tab of the report or collected in a separate or a follow on report, frequently called a Material Review Board (MRB) or remediation report. These forms continue the process by detailing and documenting any corrective action that was taken to fix the issue.

While popular in manufacturing and construction, employees in virtually any industry can use non-conformance reports to document and track quality issues and improve quality control and quality assurance..

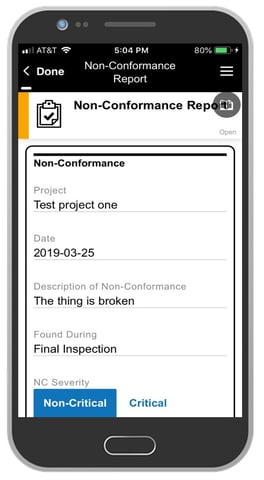

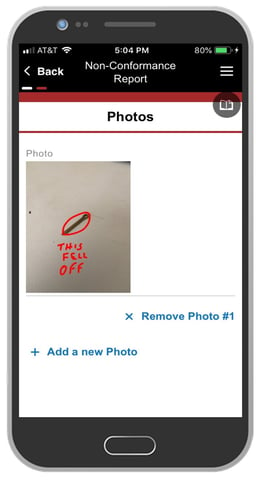

A typical non-conformance report document or form might include questions like:

These are just sample questions. It's important to make sure a NCR matches your unique product and processes to effectively identify, track and prevent quality issues. View this example of a non-conformance report template.

Once an NCR is filled out it needs to be reviewed. Usually a quality engineer, production engineer or supervisor would review the NCR, disposition the material (for rework or return to vendor or scrap), The work would be assigned to a worker to repair. Once the work was completed, it would be reinspected to verify the work was done fully and correctly.

Departments that add NCR documents to their quality management software tools or quality management systems can use NCR data and trends to identify:

Still have Questions?

Email sales@alphasoftware.com or Call 781-229-4500

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/