Quality management software helps manufacturers:

Increase product speed-to-market

Improve levels of quality and compliance.

Drive increased compliance

Enable real-time communication and collaboration

Increase overall employee productivity

Maintaining quality is crucial for organizational success in the growing competitive marketplace. Increased saturation has forced companies to expand their operations and add complex supply chains. Investing in quality management software allows businesses to quickly resolve quality issues affecting staff, suppliers, customers, and partners.

Gartner defines Quality Management Software as “the business management system” that incorporates internal quality policies and standard operating procedures (SOPs). Quality management software solutions are typically part of a Quality Management System (QMS).

QM software provides digital methods for tracking and managing quality control, quality assurance, risk management, and quality improvement. With manufacturing management software, the focus is not only on product and service quality. Quality managers can also focus on equipment and individual worker performance.

Quality management software facilitates continuous improvement. Smartphones and tablets can now augment the desktops and terminals that once tied down inspectors and quality managers. Low-code manufacturing management software allows shop floor workers to create custom mobile apps. This allows them to handle quality issues and improve workflow processes from anywhere on the production floor.

Analyzing data effectively is critical for quality improvement and continuous improvement. Manufacturers often store data in several places, which presents an obstacle to analyzing that information efficiently.

Many manufacturing companies still use cumbersome manual procedures. Often quality managers are still faced with a lot of paperwork. When they do use software, inspectors and quality managers are typically tied to desktops or dummy terminals around the manufacturing floor. In turn, quality managers spend a lot of their day tracking down missing information or correcting incorrectly keyed data.

Here's one example where accurate information is critical:

ISO 13485 is designed to be used by medical devices companies. It dictates requirements around the design, production, installation, and servicing of medical devices and related services. It has stringent quality requirements that must be carefully recorded and measured.

Quality management software that can record this information automatically, efficiently or more accurately could bring significant value to these companies. Quality managers can use low-code quality software to build custom inspection and audit apps. These apps speed data collection, ensure accuracy, and automate some data entry on the production floor.

Quality management technology provides a holistic view of data in one place and makes it easier to share and analyze. This can help identify wasteful processes, quality defects, or inefficient machinery more rapidly.

Companies can more rapidly improve quality processes and perform corrective actions with manufacturing management software. The overall result is better products and fewer customer complaints.

Quality assurance (QA) and quality control (QC) are critical to cost efficiency, production effectiveness, and maintaining customer trust, The difference between them? The goal of QC is to catch deficiencies in quality, while QA aims to minimize flaws from occurring.

Software that digitizes manual processes like reporting, auditing, and data entry improves quality control and quality assurance. The global consulting company Oliver Wyman reports that deploying digital solutions reduces quality error costs by 10%-20%.

Here are a few examples of manufacturing management software applied to business processes:

Read more on how to improve quality control.

Task-based quality management software is pivotal to any Quality Management System (QMS). Increased global competition requires companies to take the manufacturing quality management process digital to stay competitive.

Automating quality data input can dramatically impact the effectiveness and accuracy of any QMS. In fact, one study found that the average QMS implementation results in 300% ROI.

Quality control inspection software and quality assurance software solutions dramatically improves employee productivity on the production line. The software uses mobile apps or IoT sensors to help employees to collect richer data with better accuracy. A QMS with these additional apps enables top management to make data-driven decisions based on real-time, accurate information.

As part of a Quality Management System (QMS), web-based quality management software facilitates continuous improvement. Data-driven decisions remove bias. In turn, increased transparency enables organizations to ensure compliance and reduce product quality issues. Overall, customer satisfaction is improved.

The advantages of a QMS include:

Manufacturing management software is critical for collecting and analyzing data faster for continuous improvement.

Quality management software can dramatically improve quality throughout the product lifecycle. Inspections and audit management become easier. Training management is easier because they can analyze data and make decisions easier.

An end-to-end system improves the effectiveness of any manufacturer. Better manufacturing quality control software also demonstrates the implementation of best practices in processes and products.

A QMS provides better control of processes and workflows, resulting in higher quality products.

With a QMS guiding them, employees follow better processes, which results in enhanced performance and training.

A QMS helps companies collaborate and communicate efficiently with suppliers concerning the quality of raw materials or parts.

A QMS allows every department to have clear communication in relation to quality requirements, stock availability, products deployed, and much more. This yields higher quality processes that meet customer requirements and improve customer satisfaction.

Well-trained employees can also help customers troubleshoot problems, which means management has fewer issues to resolve.

Alpha Software's quality management software is ideal for creating custom apps for quality control or quality assurance. The software offers outstanding digital data collection, analysis, and reporting for any part of the product life cycle. Because the software digitizes paper processes, it dramatically improves document control and documents management.

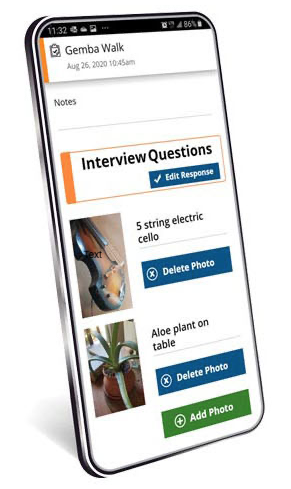

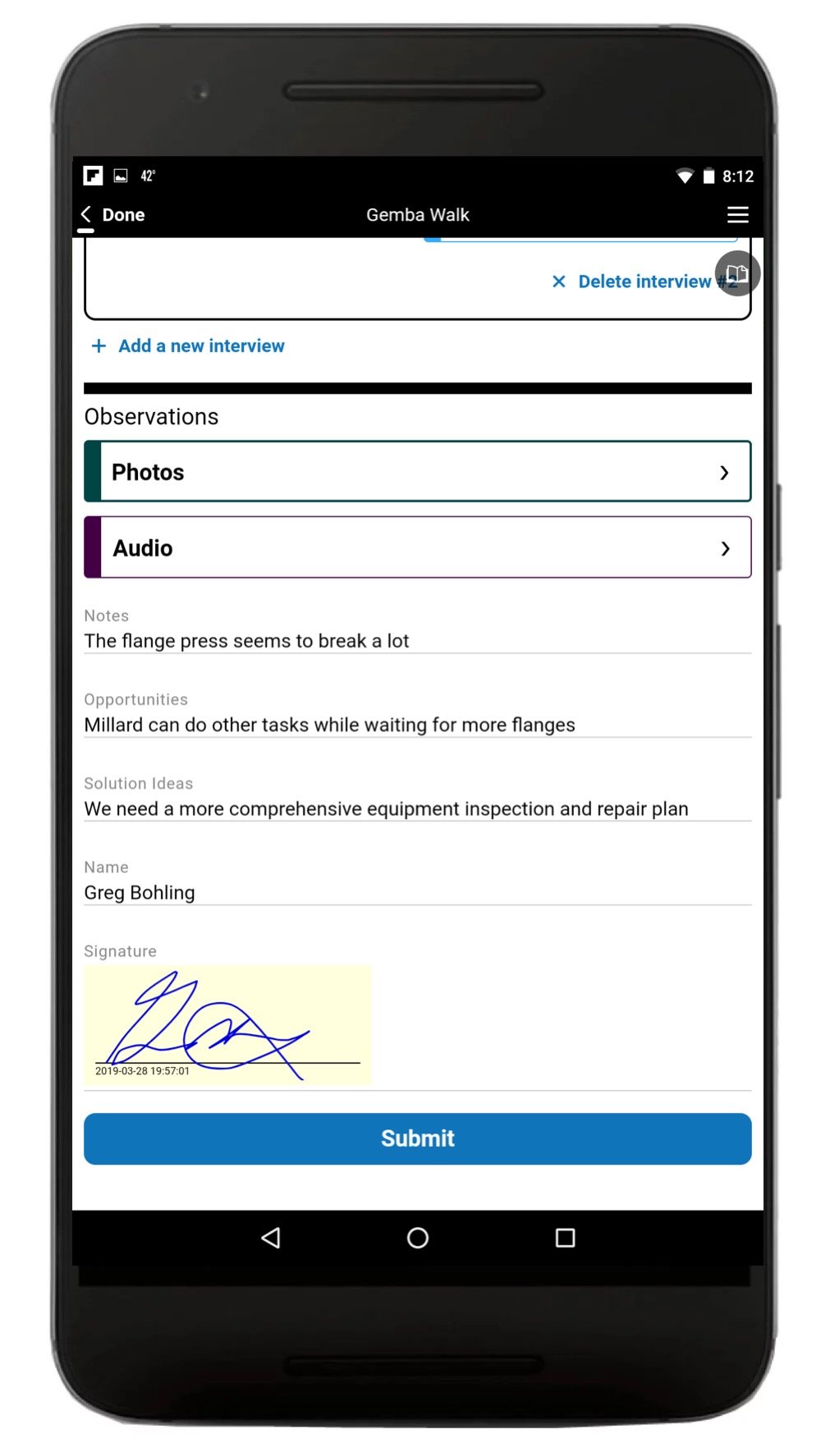

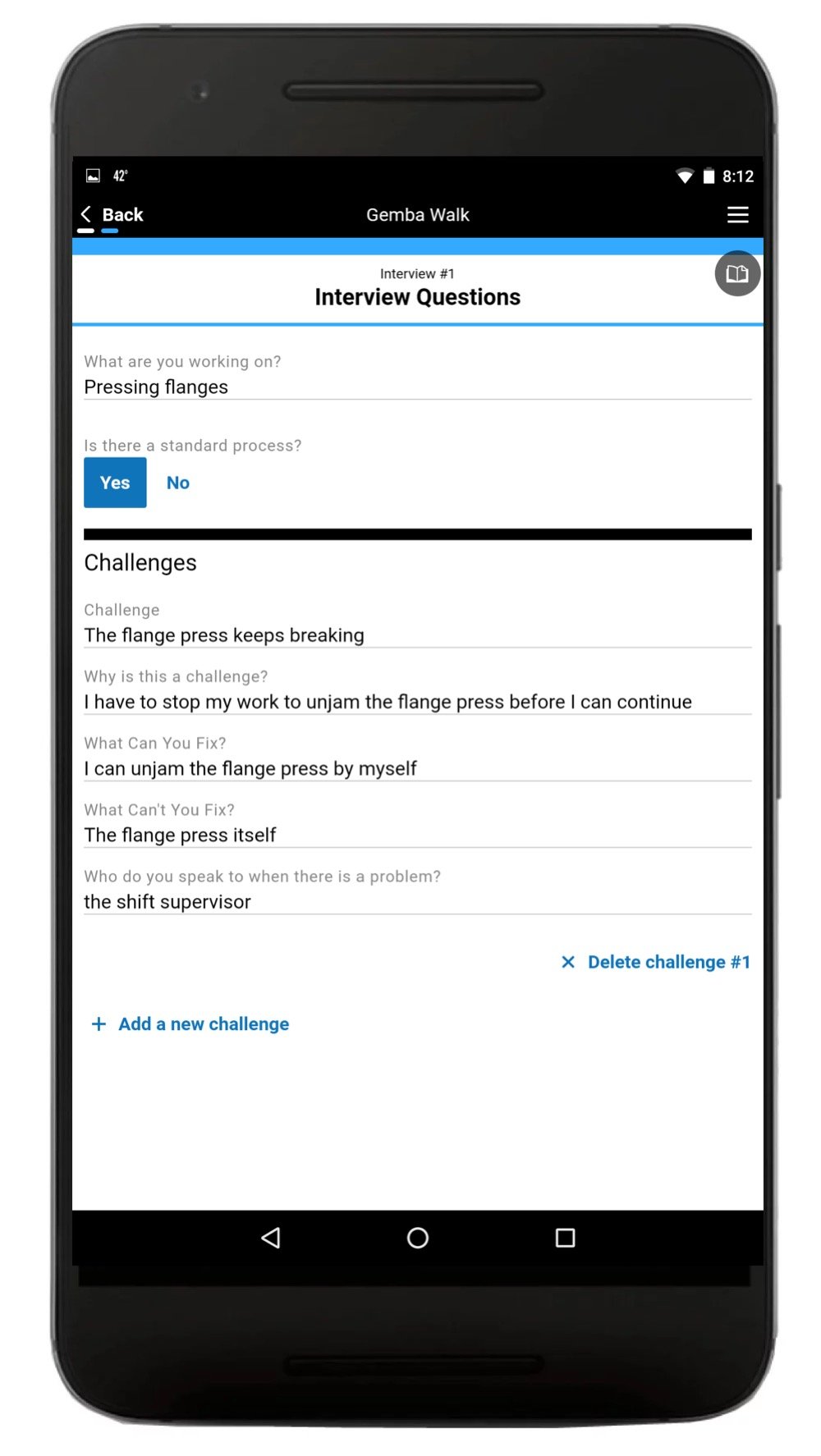

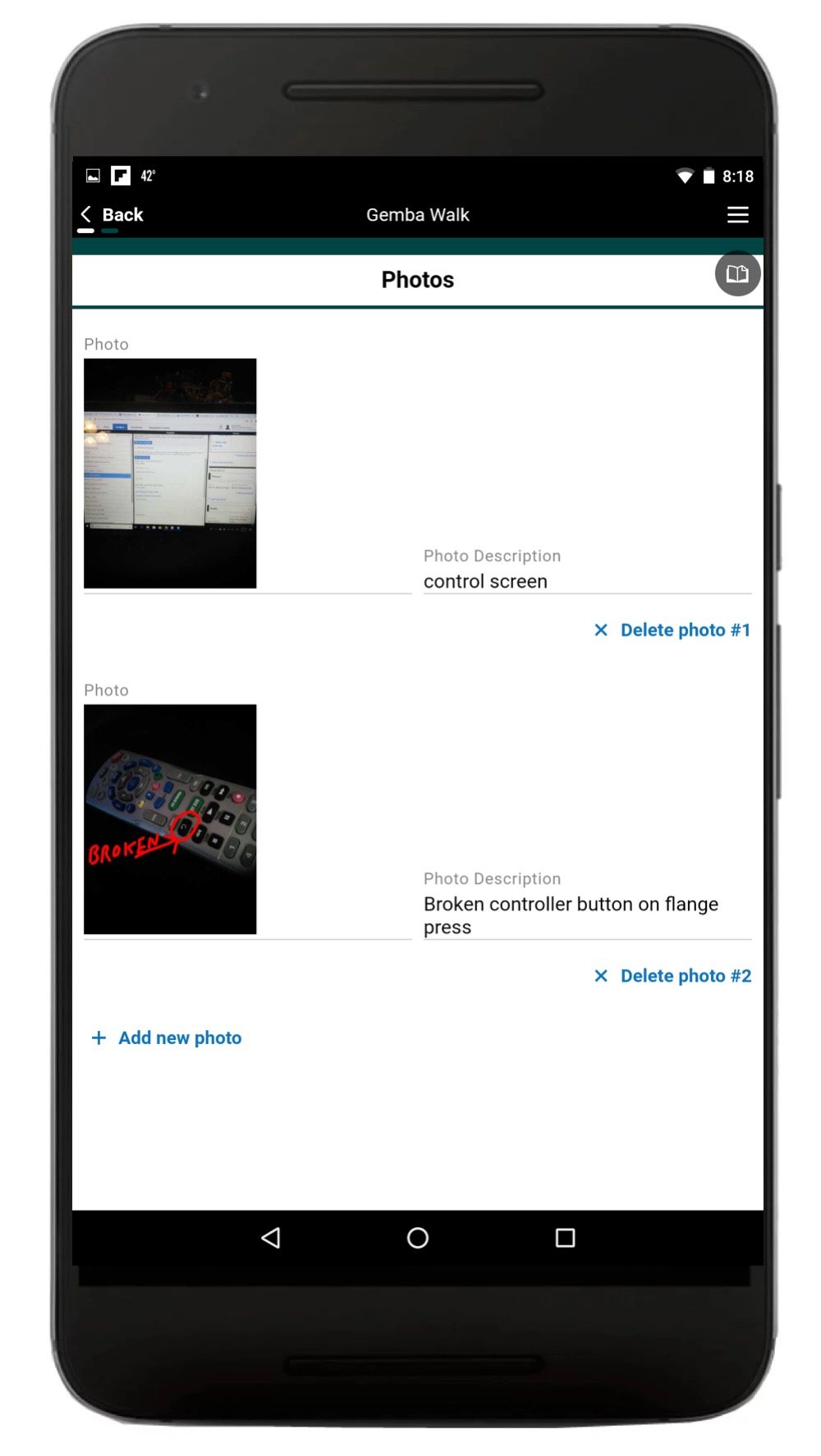

The Alpha TransForm No-Code App Builder helps business users build quality control and inspection apps rapidly. Users don't have to know app development or coding. These custom apps can leverage the latest mobile features: Camera, GPS, and more for fast, accurate data capture.

This quality solution creates custom manufacturing applications for quality data collection, analysis, reporting and audits. The software digitizes inspection forms to streamline the inspection process. The result is faster quality inspections, inspection reports, and more. The software is also a great fit for manufacturers using lean six sigma practices.

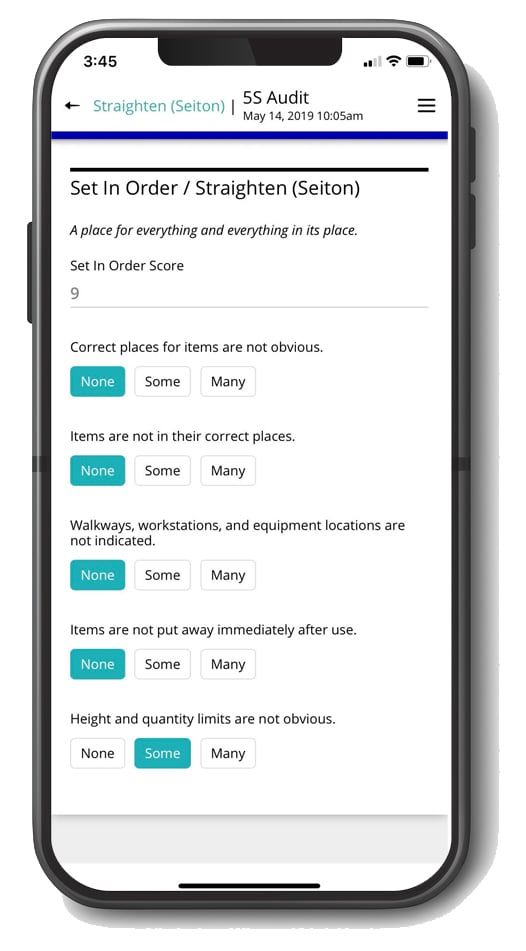

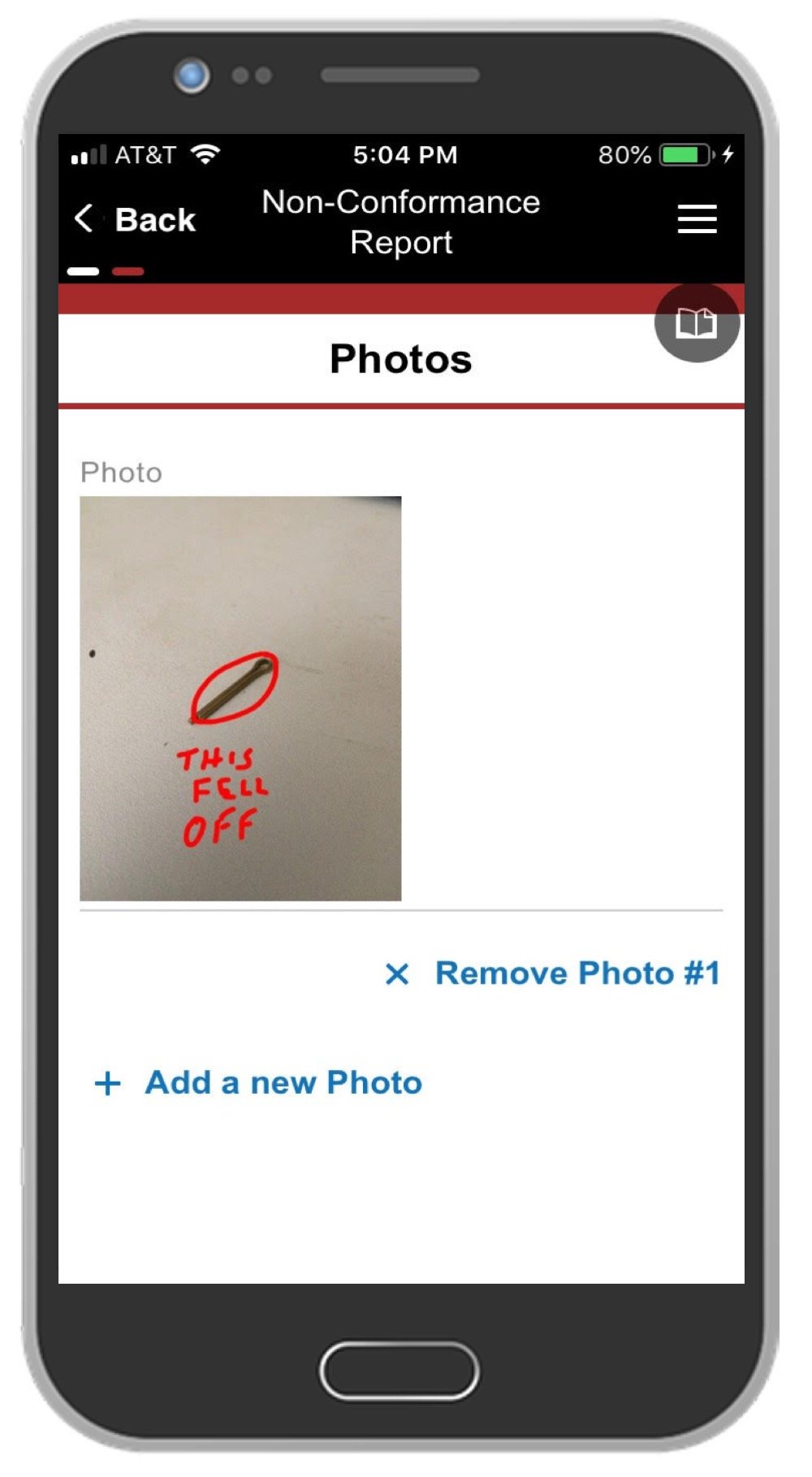

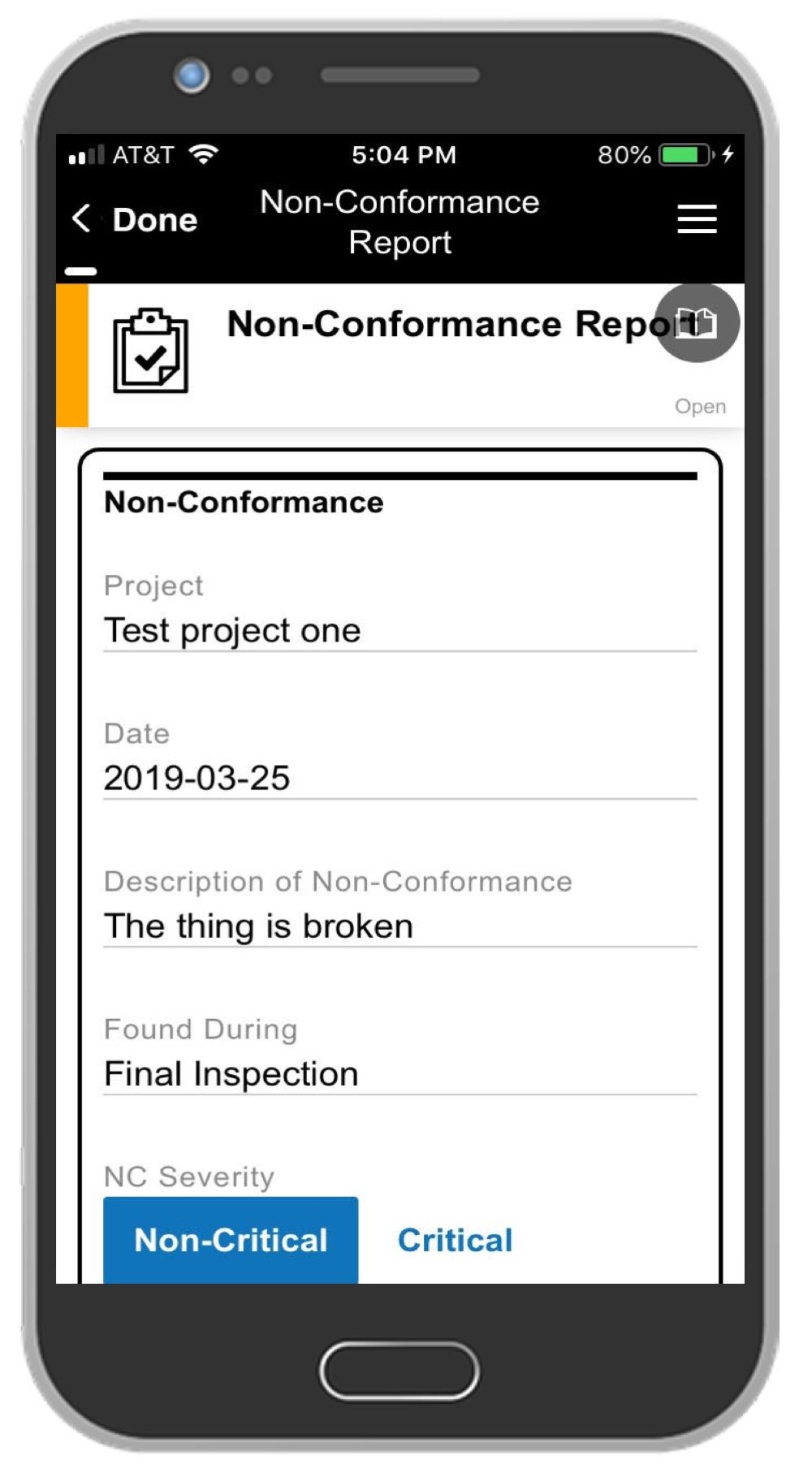

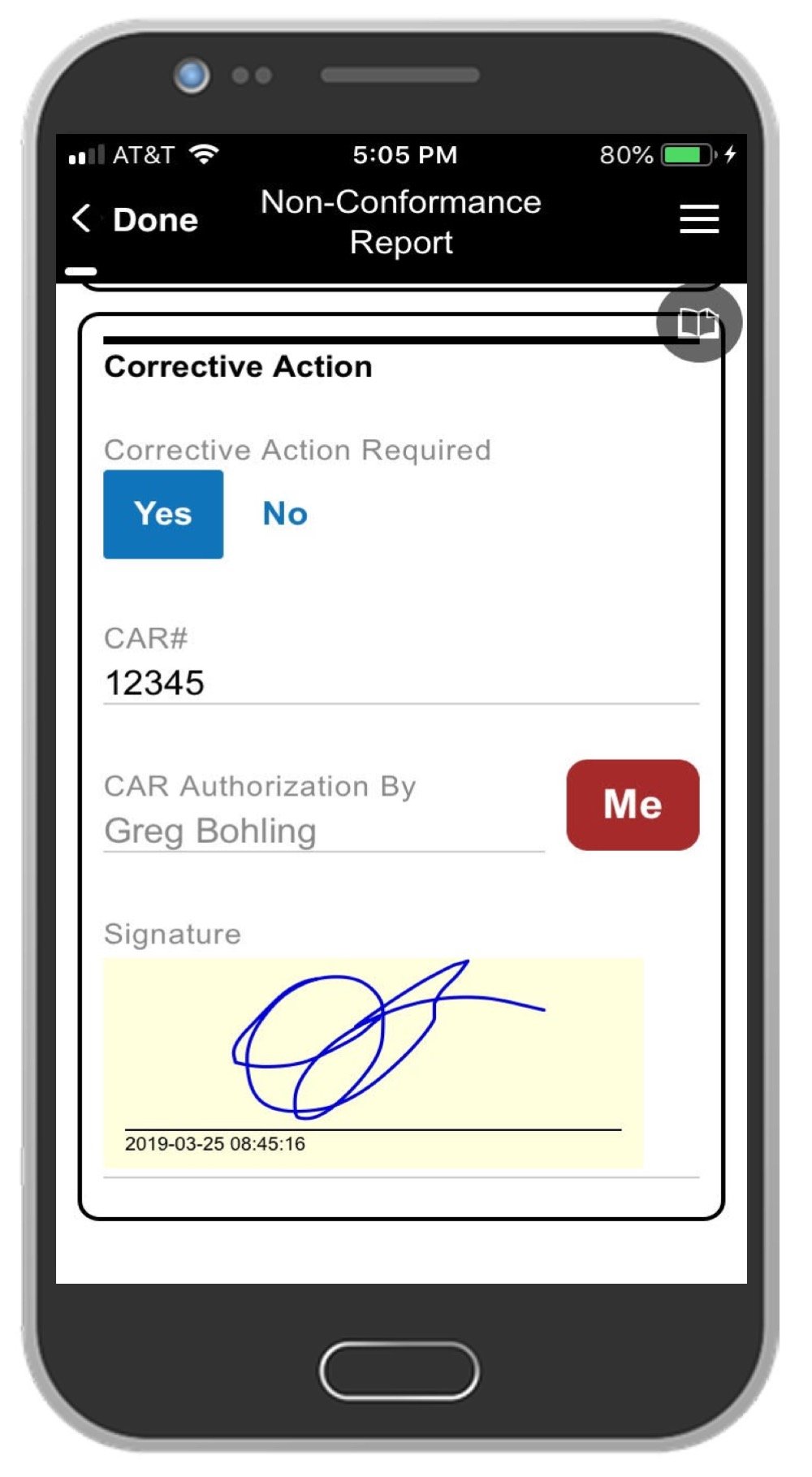

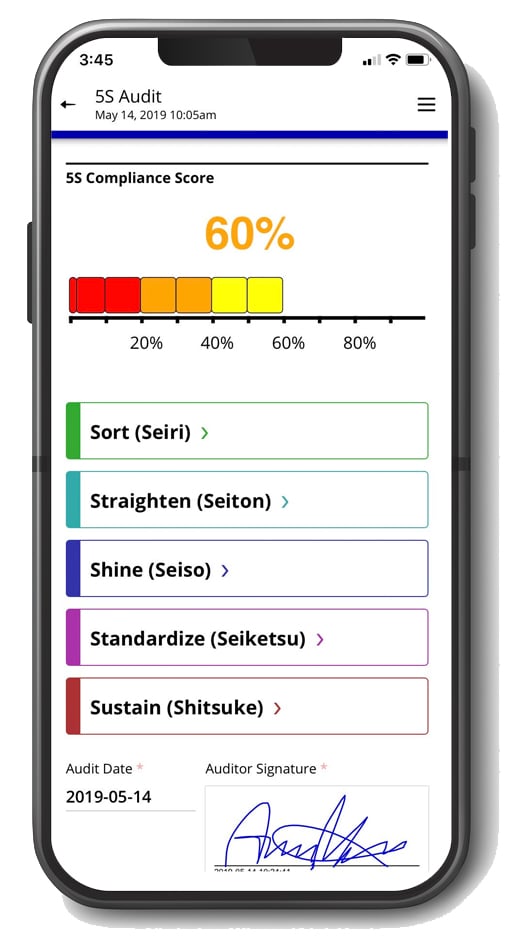

This manufacturing management software can integrate with ERP, MES, or even legacy QMS system applications for quality control needs. The mobile apps created with this software can also work without a connection. This ensures that quality control managers and inspectors are always productive, even without a WiFi or cell connection. The company offers free Gemba Walk App, 5S Audit App and Non-Conformance Report App templates you can try for free.

Quality management software ensures that quality data is collected quickly and accurately. Teams can access, analyze, and share this data fast and easily. Teams can speed up corrective and preventative action to maintain high product quality standards. Quality managers can ensure that manufactured products comply with ISO 9001 or meet government regulations.

Here are a few examples of the quality management apps working on smartphones:

Quality management software is essential for all types of large and small businesses. Studies show that manufacturing management software can improve quality standards at even the smallest companies. The software can increase production levels, raise customer satisfaction and lower the cost of quality efforts.

Research shows quality control software provides a high ROI, reduces errors, and creates continuous improvement across the enterprise. Alpha’s TransForm no-code platform offers endless possibilities for quality managers to craft custom apps.

Check out our solution for improving the best manufacturing management software on the market!

Adopt a closed loop quality managing process. with a free license.

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/