To implement quality management software successfully, manufacturers need to grasp what processes are critical to quality. They must then adopt a solution that identifies product flaws, monitors equipment, improves productivity, and reduces costs.

Small businesses need to take advantage of the latest tools, machines, and methods to improve processes, productivity, and quality standards.

However, this is costly, and some manufacturers’ may not have the budget to buy expensive solutions. Manufacturers need to be selective in their software choices and ensure that it increases quality product and reduces costs.

Here are a few ideas on how to effectively implement quality management systems (QMS) affordably.

Laurie Hendrickson, Senior Quality Manager at Locomation, says manufacturers need to develop a quality culture. A quality culture prevents errors and increases compliance. Once a manufacturer grasps its quality requirements and has selected a software system, the next stage is implementation.

International standards such as ISO 9001:2015 address critical processes, such as development quality, supply chain management, and employee training.

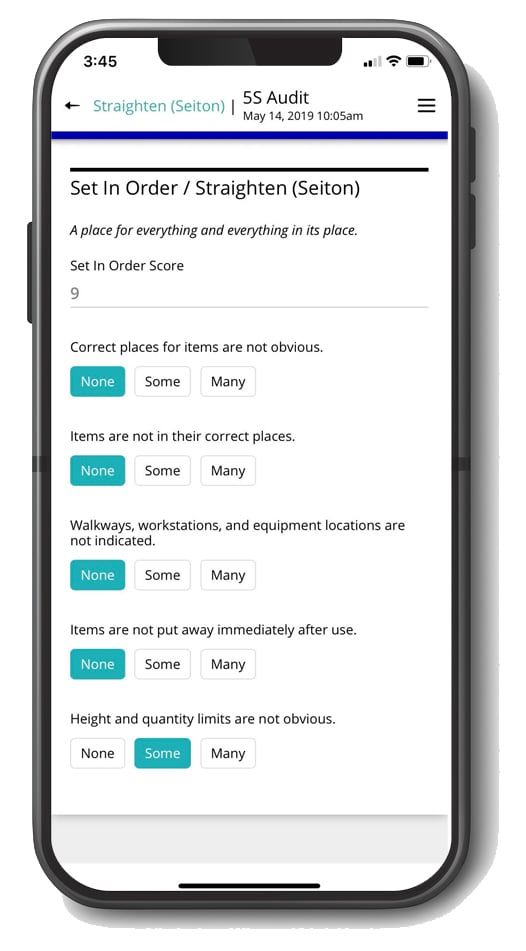

Paper-based processes are slow and are more error-prone. Paper log sheets tend to be harder to read, incomplete, and are likely to get lost. This disrupts the flow of information from the production floor to 'systems of record'. Digital checklists are less error-prone and allow a smooth flow of information.

Software for small businesses automatically routes the collected data to whoever is responsible for managing and implementing it. Digital data capture gets information into the pipeline rapidly.

Automated workflows ensure employees can quickly identify and resolve issues that require attention. Cloud-based solutions provide anytime, anywhere access. Digital quality management systems store information centrally and ensure it can be accessed from anywhere.

QMS Software solutions align a manufacturer's activities with customer and regulatory requirements while continuing to improve efficiency.

Software monitors and documents quality processes to reduce product defects and increase regulatory compliance. Quality management software streamlines operations while managing quality issues at a reduced cost.

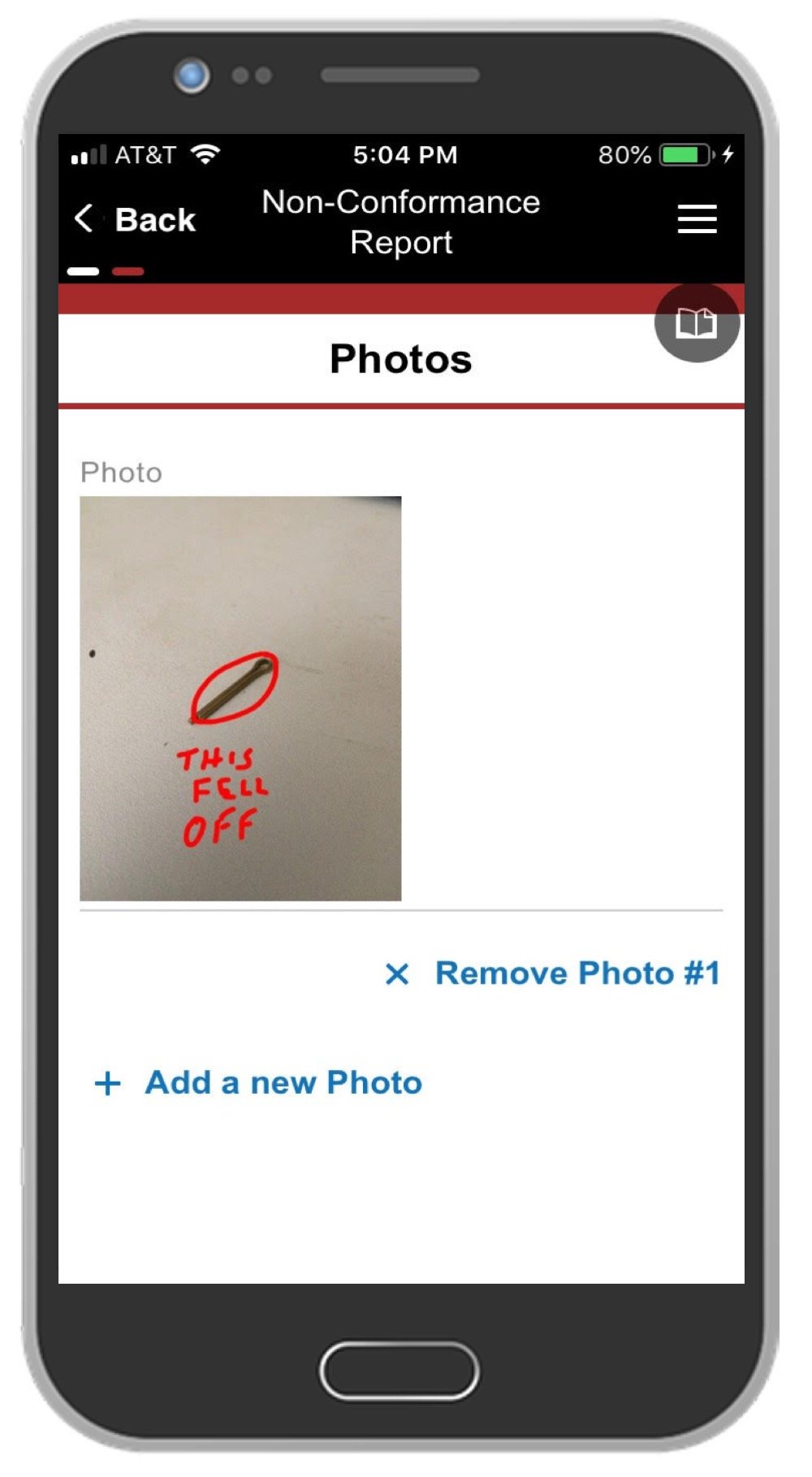

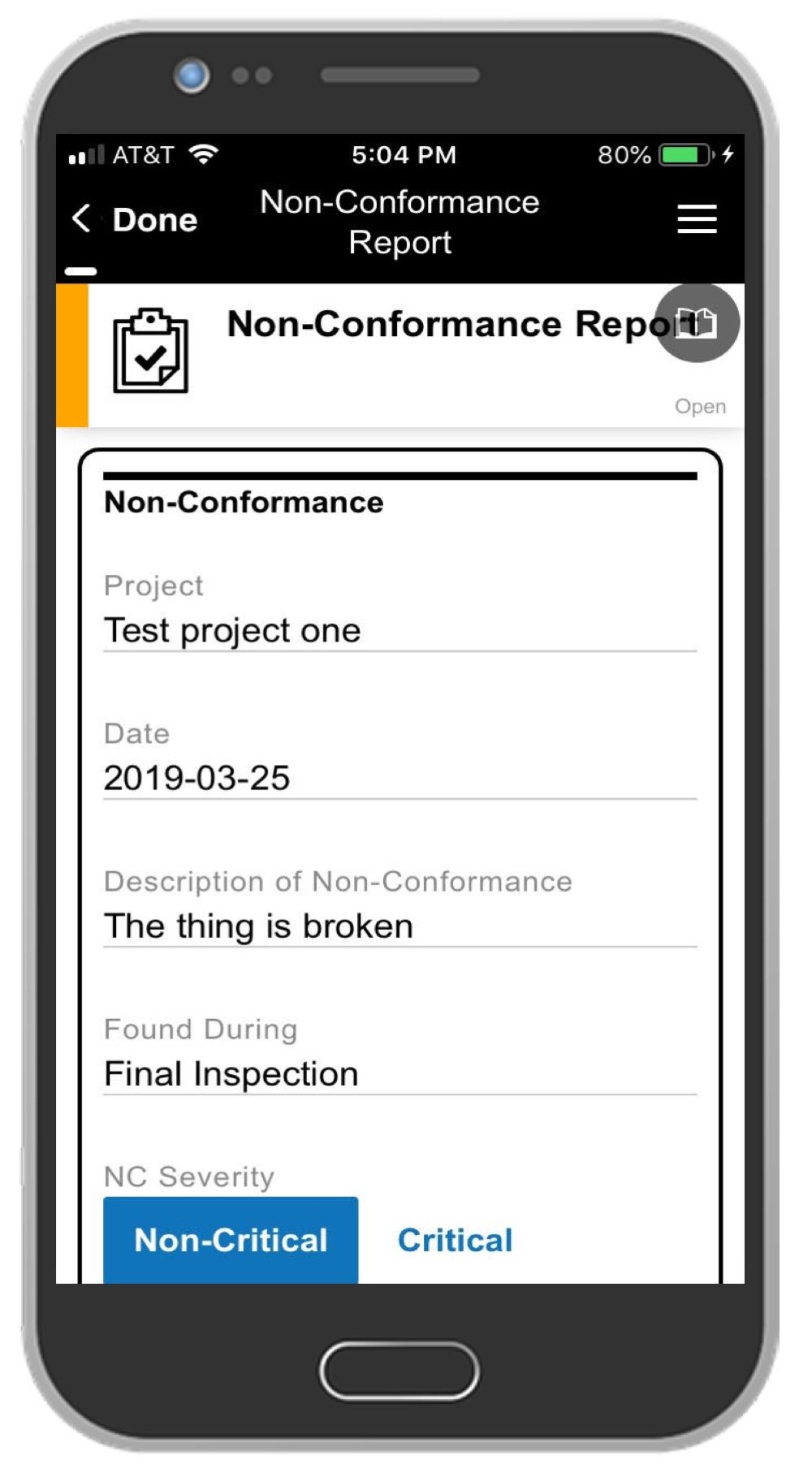

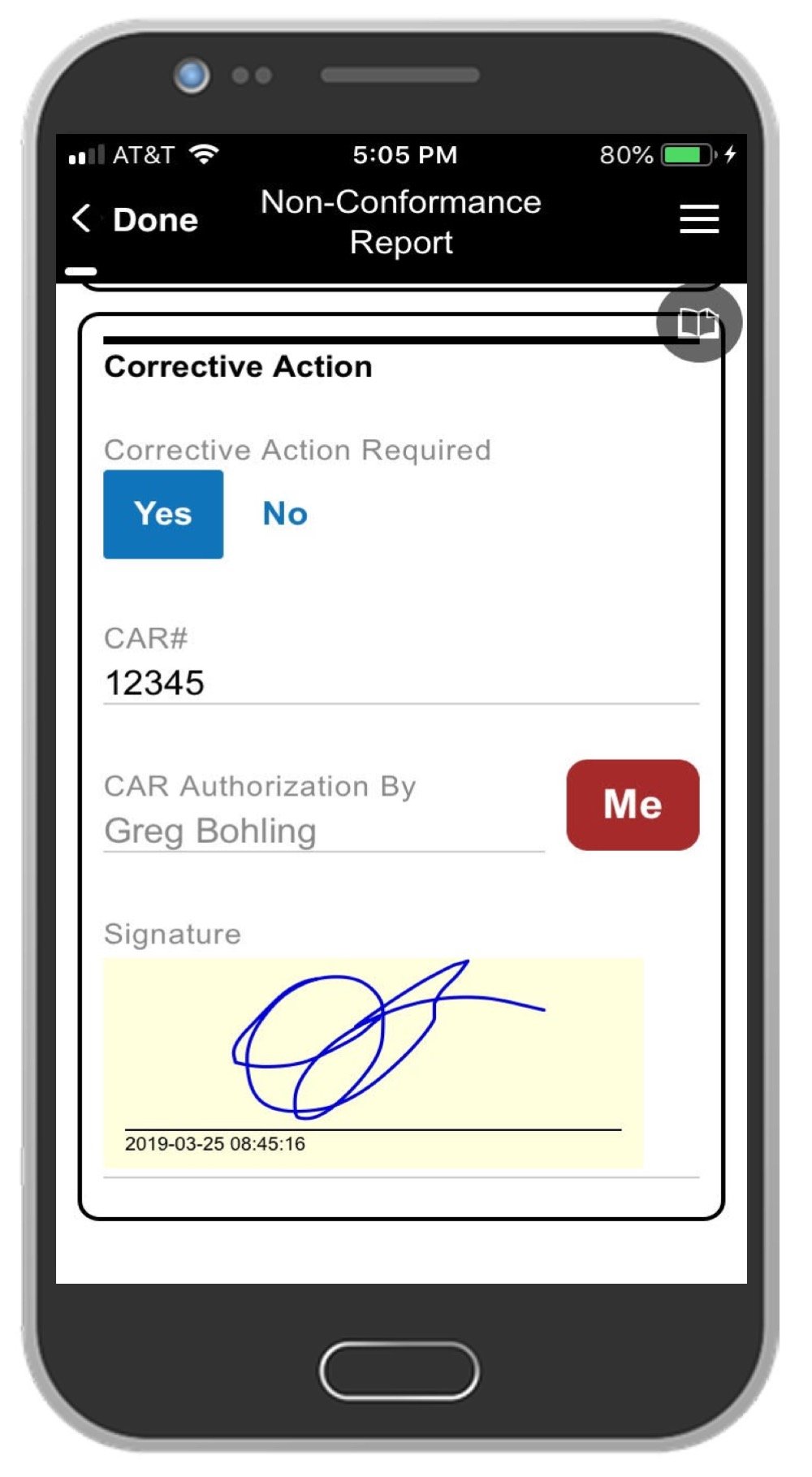

During production, Quality Management Systems (QMS) spotlight potential issues before they occur. Issues may include nonconformances, supplier problems, services, and local and global audits.

QM software monitors real-time events and anticipates events from any global production or non-production source.

Integrating quality management systems with manufacturing execution systems provides increased preventative measures, rapid risk identification, and minimal product recalls.

Statistical process control (SPC) is a method for evaluating and controlling quality. Quality management software collects data and measures it against predetermined control standards. SPC software analyses data to identify specific causes of production defects.

Failure mode & effects analysis identifies potential failures in the assembly or manufacturing process design. Failure modes are the ways in which a process could fail, especially if the customer is affected. Impact analysis examines the consequences of these failures to take preventive action.

Defects are prioritized according to the severity of their consequences, their frequency, and visibility. The purpose of FMEA is to eliminate the risk of errors, starting with those that most affect the company.

Advanced product planning ensures quality and performance through planning. The objective is to meet customer satisfaction standards. APQP is a system that is a set of quality requirements that guides the design of a product. The goal is to help employees collaborate between engineering activities.

Total Quality Management (TQM) focuses on every manufacturing phase. The objective is to retain quality from inception to the end product. Many organizations use this technique because is easy to implement and is less costly.

Six Sigma is a collection of quality control tools designed to eliminate defects and improve processes to increase profits. The objective is to reduce manufacturing defects to no more than 3.4 occurrences per million units or events.

QMS Software for small business can dramatically improve quality throughout the product lifecycle.

Small businesses have fewer resources than their larger counterparts, but that doesn't mean they can't make smart investment decisions. Research shows that the money spent on quality software saves costs.

It costs 10X more to correct a product defect after it reaches its customers than identifying it ahead of time. The American Society of Quality found that it costs a tenth of that to invest in software to prevent issues.

Manufacturers need software that accurately analyzes data, specifies key indicators, and identifies potential issues. The latest technological solutions allow factory workers to play an integral role in reducing potential problems and improving quality.

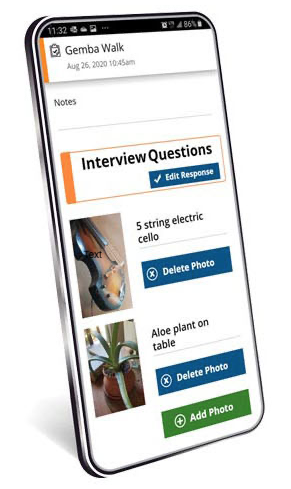

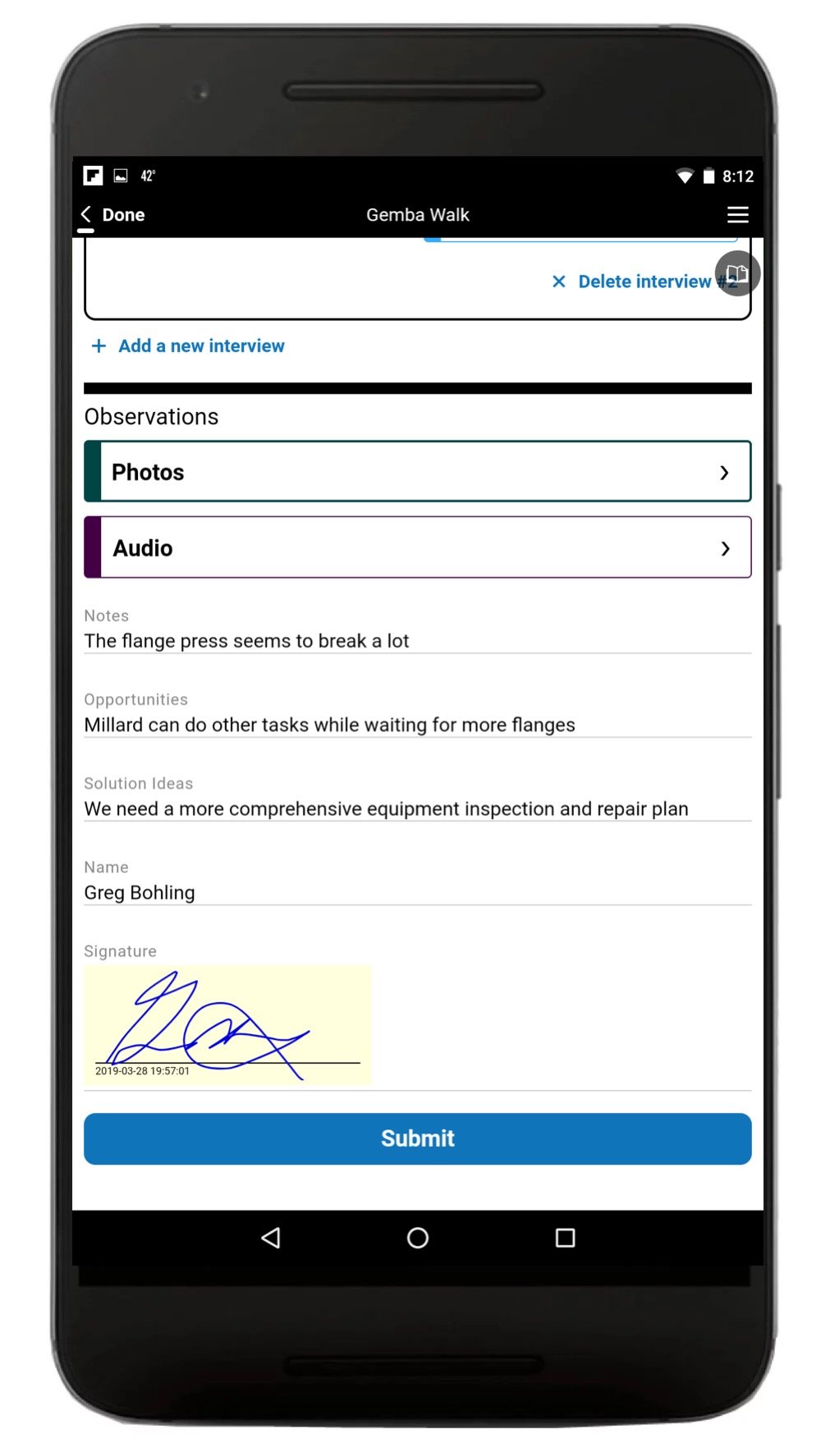

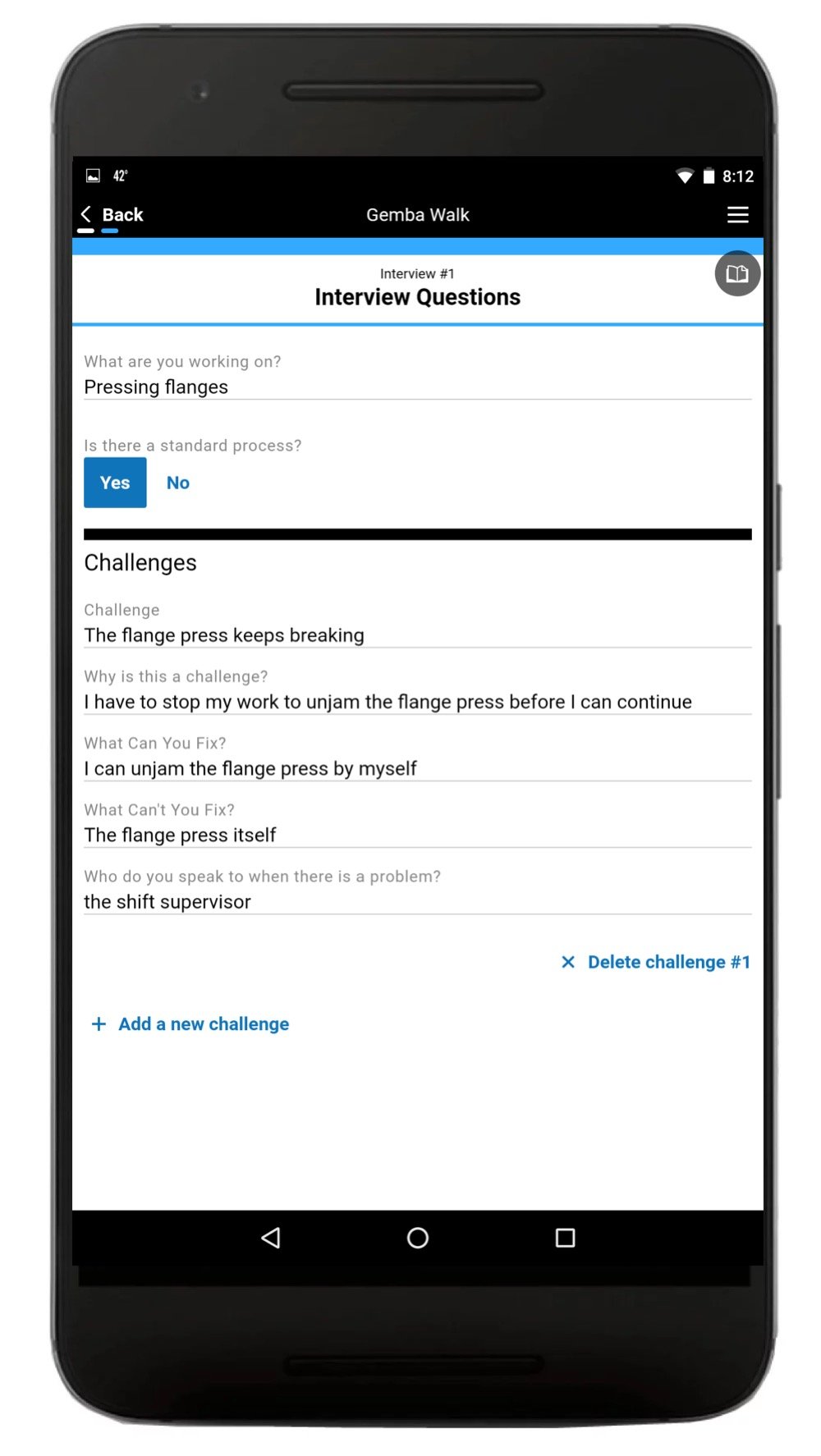

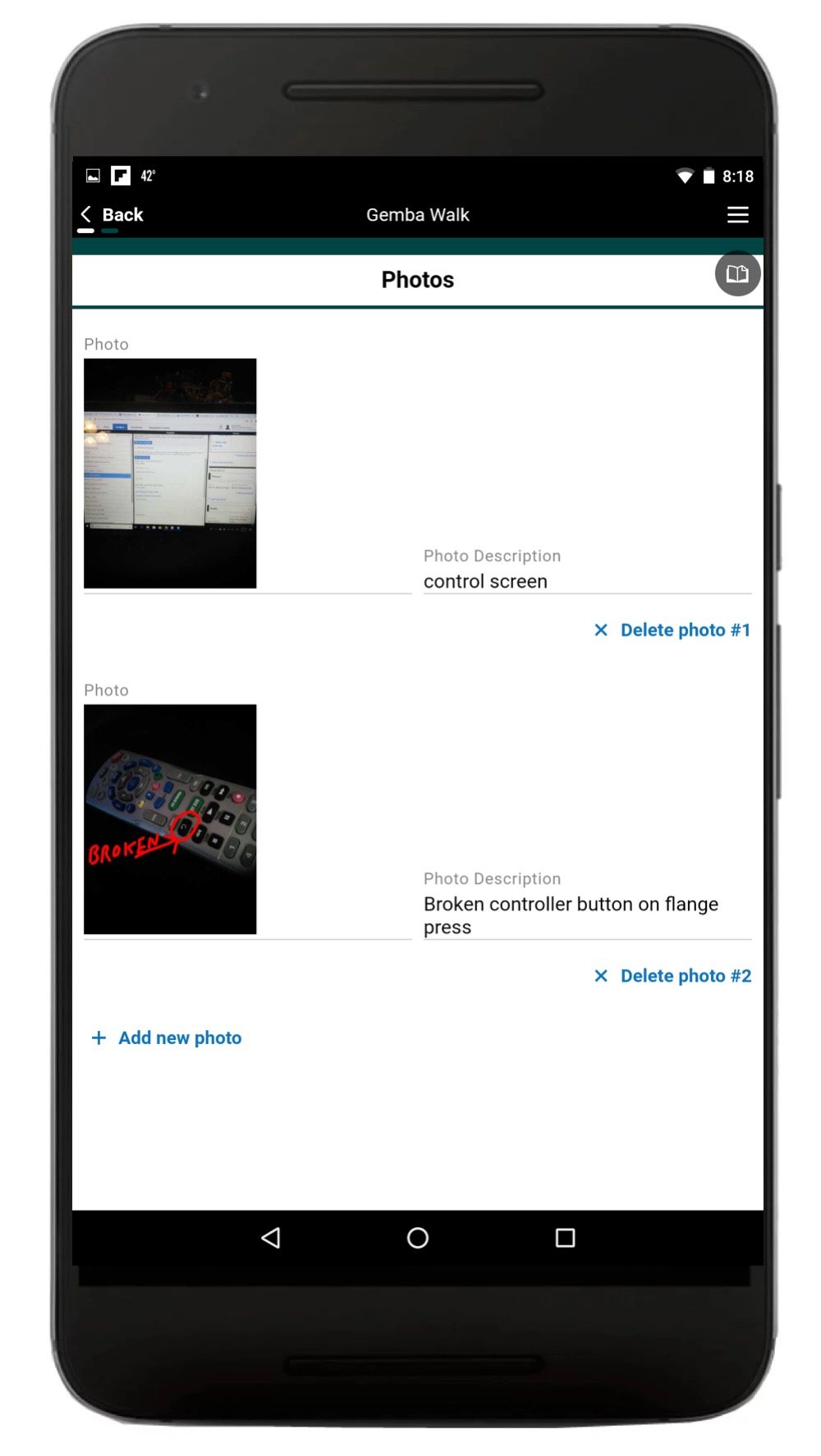

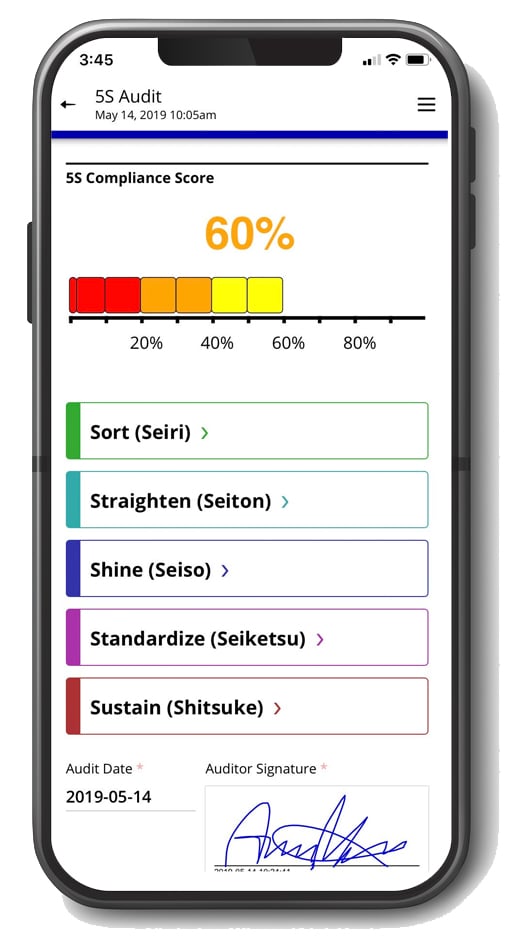

Digital solutions report quality issues, increase collaboration, and boost communication while reducing rework and scrap across entire production lines. For example, software solutions from Alpha Software enable employees to take quality control inspections, audits, and other processes digital.

Many businesses use a waterfall approach to manage processes. The advantage of this approach is that it is thorough. Everything from documentation to testing needs completion before moving on. The downside is that it increases bureaucracy and limits flexibility.

The Agile approach involves making short iterations throughout the design, testing, and product launch stages.

Small manufacturers need a dedicated technology partner that will:

Small businesses need to collect and analyze data that is critical to quality manufacturing. Alpha TransForm manufacturing solutions can ultimately resolve issues, reduce costs, and increase productivity. And we can map the solution directly to your unique process and data sources.

Quality management software is essential for all types of manufacturing businesses, especially smaller companies. Studies show that it improves quality standards while increasing production levels and customer satisfaction. It can also lower the cost of quality efforts when it's used for preventative measures.

Research shows QMS software provides a high ROI, reduces errors, and creates continuous improvement across the enterprise. Alpha’s TransForm manufacturing solutions offer a range of possibilities for continuous improvement.

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/