More manufacturers are recognizing the benefits of low-code. The use of low-code platforms keeps on growing. According to Gartner, “By 2024 75% of large enterprises will be using at least four low-code development tools for both IT application development and citizen development initiatives”.

In the manufacturing industry, there is an increasing shift towards digital transformation. Many leaders have benefited from adopting Artificial Intelligence, Augmented Reality, and Additive Manufacturing innovations.

Industry 4.0 has dramatically changed manufacturing, and the results are being felt across the board. Increasing numbers of manufacturers are using mobile devices, IoT, data analytics, the cloud, and more. By using modern technologies, companies are achieving greater efficiencies and lowering costs.

Organizations have realized that low-code software development has several advantages. Engineers can create applications that address manufacturing problems. Experienced developers can focus on urgent tasks as employees can independently create solutions. IT teams and business users can also collaborate on low-code projects.

Low-code development is critical for improving manufacturers’ performance, production, and input. Large companies are already using technology, machine learning, and Artificial Intelligence.

However, due to costs and logistics smaller companies are slower to adopt smart manufacturing tools. Low-code offers them the opportunity to gain ground on their larger competitors. Here are some ways how low-code can improve the manufacturing industry.

Low-code is an essential part of the movement towards smart manufacturing. According to recent research, 80% of companies see smart manufacturing as a key contributor to their future success.

Manufacturers use low-code because it allows their non-technical staff to collaborate with professional development teams. In addition to digitizing workflows, improving factory automation, and supporting field workers.

More Accessible App Creation for Citizen Developers: Companies have found that citizen developers come from various departments. Business analysts, who spend most of their time working with Excel and BI tools, find low-code platforms easy to learn. Industrial engineers who are well-schooled in model-driven development also find low-code tools to be easily accessible.

Improves Efficiency and Accelerates Innovation: Manufacturers build low-code applications to enhance logistics, inventory management, and supply and operations planning. Business users are also creating applications that offer insights that support decision-making. By developing applications for field services and core business use, it helps transform factories into digital enterprises.

Resource Management in manufacturing typically involves the use of an ERP system to plan the effective use of resources. While Enterprise Resource Planning Systems are an improvement over MRP II systems, they do have limitations.

A Low-Code ERP System: To upgrade an ERP system typically requires hand-coding. In many cases, companies need to enlist the help of an outside consultant. Changes made to an ERP force updates to a company's reports and workflows. Gartner, Forrester, and others support a more user-friendly ERP, a faster, more digital approach that accelerates application development.

Modern cloud-based ERPs use a "clicks not code" approach. Using point-and-click and drag-and-drop tools, factory workers can develop powerful, user-friendly applications. ERP systems built on low-code platforms are graphical and modular. This means users can make changes themselves without increasing IT workloads.

More Tailored Options: Low-code platforms have built-in controls and security features. Unlike older ERP systems, companies can benefit from upgrades and new releases. Low-code ERP systems have business logic built-in and customizable modules and features.

Low-code ERP systems minimize the need to code by hand. Users can easily create applications that make business processes and workflows more efficient. This means they can actually focus on what they need to see on their screen to get their work done.

There are several low-code and no-code use cases for manufacturing. Here are examples of some of the most important. In the manufacturing industry, machines are usually connected together. If one machine has an error, it will affect the others.

A dashboard application for managers can be used to monitor the entire manufacturing process. If one machine experiences a malfunction, the application sends an alert to other systems. An analytics-based dashboard application provides meaningful insights to improve production and effectively allocate materials and the workforce.

Paper instructions can be difficult to understand and follow. They are also not interactive and can make work tedious. A low-code visual work instruction application can be used to train employees on how to operate manufacturing systems. Visually interactive videos showing different scenarios and use cases could improve employee familiarization.

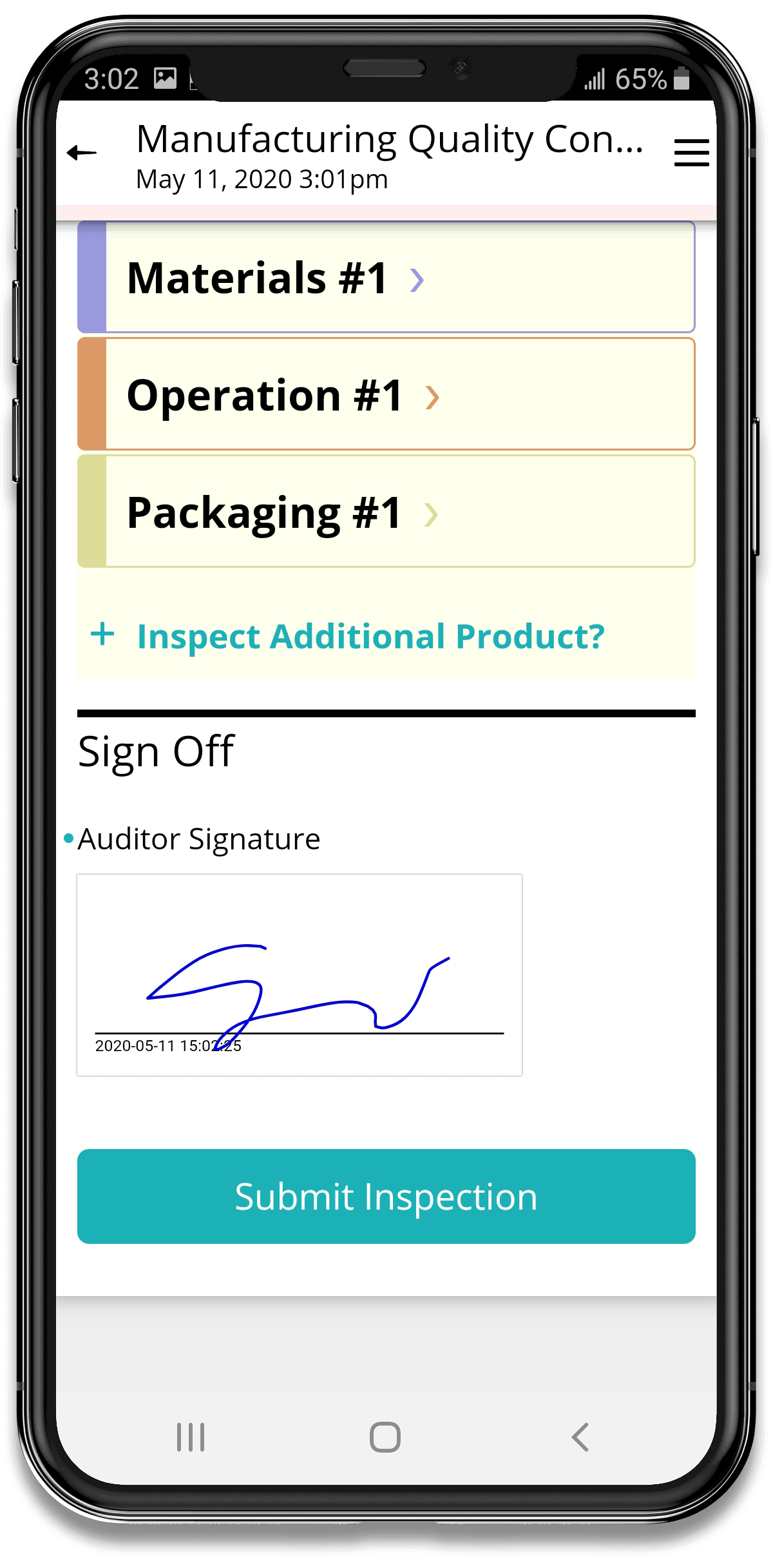

Quality control is critical in the manufacturing industry because substandard products can damage a company's reputation. With a quality control application, the quality of raw materials and production processes can be monitored with tickets that signal defects. Inspection reports can be generated and sent immediately to stakeholders to provide an overview of the manufacturing process.

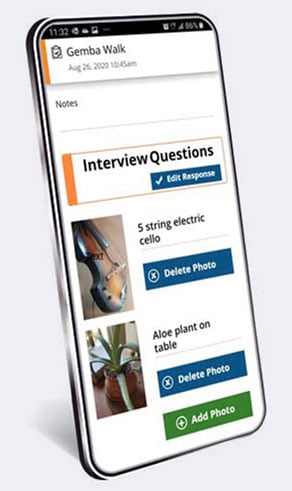

Many manufacturers have realized that mobile applications have several benefits, such as streamlining communication and sharing information. Off-the-shelf applications like Salesforce and Dropbox make manufacturers' work more efficient. Perhaps the greatest benefit, however, comes from developing applications that can be customized.

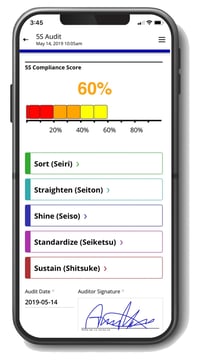

Using low-code application development, manufacturers can create customized solutions that meet their specific needs. For example, shop floor workers can develop apps to turn machines on and off while providing material flow analysis. Many companies use Alpha TransForm to develop mobile applications that help field workers to complete tasks without a Wi-Fi signal.

Low code development software can speed app development for manufacturers and still allow custom solutions.

Managers can use mobile applications to stay informed about everything that's happening in and out of the plant. The applications allow them to access employee, inventory, shipping, vehicle, and delivery data. Mobile solutions also increase the accuracy of data needed for quality control and OSHA inspections. As a result, inspections run much more smoothly.

Read more on the benefit of using mobile apps for manufacturers.

The Industry 4.0 revolution is enabling stronger communication between managers and workers in the factory. It also creates a fluid exchange of information between manufacturing plants and their external suppliers, distributors, and customers. Digital technologies like Artificial Intelligence, Industrial IoT, and Digital Twin are playing a crucial role in this revolution.

However, the demands of Industry 4.0 are making some manufacturers wary of adopting these technologies. This is where low-code offers immense value. It is relatively easy to learn and connects people, processes, and machines. Rapid Application Development is a driving force that enables connectivity between manufacturing plants and customer sites.

Low-code with Artificial Intelligence and Machine Learning has improved back-office operations by strengthening the connection between core systems. They allow companies to use data from these systems to create insightful analytics. This information is then used to improve operations and drive business results.

Manufacturers use low-code platforms because the initial cost of setting up, deploying, maintaining, and training applications is lower. This is especially beneficial for small and medium-sized businesses. These companies want results but may not have the resources, budget, or in-house expertise to undertake a comprehensive digital transformation.

Low-code platforms also integrate easily with ERPs, MESs, and CRMs, and smart devices. Manufacturers have used low-code to create smart factories where there is a constant flow of communication between the factory floor and corporate offices.

There is also centralized visibility of data processing across multiple factory units. Business users can create low-code applications that help manufacturers better plan operations, deliveries, and logistics. Custom applications streamline the introduction and launch of new products. Managers also use applications to monitor specific machines and equipment.

Low-code benefits manufacturers from the factory floor to the enterprise level. Business users can build applications easier and faster. Low-code solutions also improve communication and information sharing inside and outside the company.

Applications can improve supply visibility, inventory management, monitoring of machinery and equipment, and increase supply chain efficiency. Small and medium-sized enterprises can use solutions that make digital transformation more cost-effective and efficient.

Whatever your manufacturing process, Alpha Anywhere is the best low-code software for developing manufacturing apps. We've made it easy to get started with Alpha Anywhere Community Edition -- a FREE development environment. We also have a team of experienced app developers who can show you how to build apps.

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/