In order for manufacturers to survive, they need to rebuild themselves using digital technologies. This digital transformation isn’t merely a “nice to have” — it’s a “must-have.” So concludes the IDC report, Digital Transformation in Manufacturing: Creating Intelligent and Connected Businesses. The report puts it succinctly: “Manufacturers worldwide are rapidly embracing new technologies to transform their business models and operations to improve agility, customer engagement, profit and sustainable competitive advantage…In the face of new and disruptive competitors, they are changing their businesses radically to offer value-added services and leverage tightly linked ecosystems.”

The report points to a host of technologies at the heart of digital transformation, including the cloud, big data, AI-assisted analytics and the Internet of Things (IoT). And enabling all of those technologies, and binding them together, it points out, is mobile.

To truly transform an enterprise, the technologies they should work together in what IDC calls Enterprise Information Management (EIM), which acquires, structures, mines and uses data. EIM, the report says, “improves efficiency, transparency, business insight, decision making and customer engagement to deliver better business results in the new digital economy.”

Mobile technology enables EIM in multiple ways, the report says. One example is in the link between the cloud and big data analytics. Big data analytics requires massive amounts of data and processing power to yield its insight — power and storage which is provided by the cloud. The report notes, “The synergy between cloud and big data analytics, amplified by the widespread distribution of mobile tools, will prove to be key.” Mobile tools can be used to gather data -- such as from non-conformance reports -- send it to the cloud and back, and then distribute the results widely, including to people on the factory floor running manufacturing processes.

The report goes on to say, “Manufacturers are on the verge of a revolution in the way they use information. Everybody will need to access information through cloud, mobile tools and even wearables. Be aware: the more information that is available, the more it will be requested by shop floor users and other business units.”

The report concludes that connectivity — and therefore mobile technologies — are the glue that binds EIM together: “The fundamentals of a smart manufacturing initiative will require secure plant floor connectivity – for IP equipment and mobile devices, analytic capabilities (either in-house or sourced), robotic skills (hardware & software), system integration from shop floor to top floor and possibly customer to supplier, and IT/OT integration.”

The report concludes that connectivity — and therefore mobile technologies — are the glue that binds EIM together: “The fundamentals of a smart manufacturing initiative will require secure plant floor connectivity – for IP equipment and mobile devices, analytic capabilities (either in-house or sourced), robotic skills (hardware & software), system integration from shop floor to top floor and possibly customer to supplier, and IT/OT integration.”

The Best Platform for Building Quality Manufacturing Apps for Digital Transformation

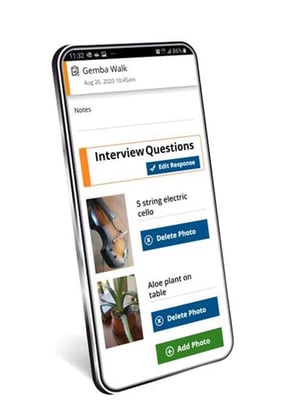

The Alpha TransForm Quality Manufacturing Solution can digitally transform your business. The solution utilizes mobile device features (camera, GPS, time/date stamping, etc.) for fast, accurate data collection. The data can immediately be shared or analyzed using built-in dashboards we can customize for your KPIs. The resulting quality control and quality assurance apps can then tie into any corporate system of record to make the data available for use immediately, or to power workflow processes that initiate an emergency stop, take corrective action or trigger order replacement.

Book a Meeting: Tell us your business problem and we'll build the solution you need.

Want to move even faster to digitize your paper processes? Let us customize one of our sample apps for your use, such as our Gemba Walk App, our 5S Audit App or our Non-Conformance Report Template.

Comment