Manufacturers need to use a combination of Six Sigma Solutions to ensure consistent process improvements and to achieve a positive ROI.

The goal of Six Sigma is to significantly improve manufacturing processes by identifying and eliminating product defects while improving product quality. Organizations use a sigma rating to demonstrate the percentage of defect-free products.

A Six Sigma process would show that 99.99966% of manufactured products have no flaws. Manufacturing processes where the Six Sigma method is applied result in approximately 3.4 defects per million products.

Any organization's main objective is to enhance processes while increasing profit. Six Sigma techniques and tools help reduce costs and eliminate errors while improving customer satisfaction. Software can make the process of instituting Six Sigma techniques easier.

The Six Sigma methodology defines a problem first, measures it, uses data to identify a root cause, then implements a solution. Manufacturers then continue to control improved operations to prevent the recurrence of issues.

In addition to understanding Six Sigma, organizations need a strategy. The first stages in a project are to establish a common goal to minimize product flaws and define objectives for excellence. There are various Six Sigma standards from white belt to green belt to master black belt.

Standardizing processes to achieve Six Sigma excellence enables employees to focus on reducing the standardization within individual projects. Standardizing a unified approach reduces project execution times and encourages a team-focused culture.

Mapping out a plan helps keep quality programs focused. During this stage teams need to be identified and processes scheduled.

Although Six Sigma and Project Management have similarities, there are also differences. They are both implemented by teams working in different departments and have multiple phases involving project planning.

However, project management and six sigma methods are also different. Six Sigma follows DMAIC (Define, Measure, Analyze, Improve, and Control) phases, while project management follows initiating, planning, executing, monitoring, and closing phases.

Six Sigma requires a commitment to the process from project teams. At the start, teams need to work together to develop a charter with project objectives, then set milestones for improvement. In the final stages, teams create documentation that explains how to maintain improvements in the long term.

Project management focuses on getting a project off the ground instead of refining process performance. It uses the critical path method to ensure that projects are completed efficiently. It is also more effective at providing a one-time implementation rather than continuously improving existing processes.

Project management lacks the tools to measure performance and apply solutions for continuous improvement. Instead, project management evaluates the different components of a project's performance.

Manufacturing companies use Six Sigma to eliminate waste within production processes. Six Sigma tools are techniques and methods that support making changes to processes. If used well, Six Sigma tools can minimize waste, boost productivity, and increase profit.

Many companies apply a Kanban two-card system. T-Kanban transport cards inform employees when containers need to be moved to the next stage of the production line. P-Kanban cards provide a fixed quantity of products or parts that a work station must produce. One of the main goals of Kanban is to limit a pile up of excess inventory

Pareto charts visually represent the Pareto principle. That’s 20 percent of input yields 80 percent of output. They include a vertical bar chart and a line chart. The bar chart shows various metrics of process components. The line chart shows the cumulative sum of all metrics.

Business process mapping visualizes business processes. A map usually outlines roles, responsibilities, and standards in a manufacturing process. It shows data in a structured way, the stages involved, who is responsible, inputs and outputs, and other information. By visualizing a complete process, it is easier to specify root causes of issues.

There are several stages involved in implementing a Six Sigma Project. Some of the main ones are included below.

Gaining Strategic Management Support

The main starting point is to gain support from strategic management. Everyone must participate, understand the need for improvement, and commit to actively embracing change in a product or service. Implementing Lean Six Sigma needs to be integral to an organization's strategic goals.

The steps needed to implement Six Sigma include raising awareness, establishing responsibilities, and focusing on value-added activities for customers. Once defined, it must be measured against existing systems to identify opportunities for improvement.

TBD

An essential stage in a project is to collect data on specific problems. Then use tools to measure the entire issue. Value Stream Mapping identifies problematic phases of workflows and all non-value-added activities. Gantt Charts help project planning and show relationships between the start and task end dates, milestones, and dependent tasks.

Greg Jacobson, CEO of KaiNexus, identifies 6 Critical Features of a Best-in-Class Lean Management System which includes:

A way for employees to suggest opportunities for improvement whenever they see them. A digital whiteboard for daily meetings, scorecards for improvement, increased access to information, and real-time alerts and notifications.

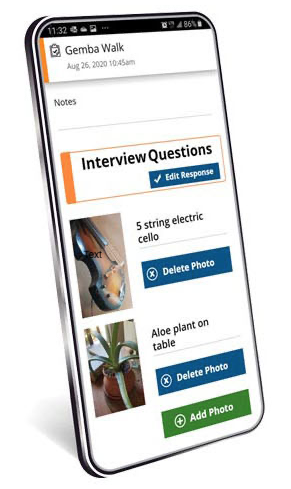

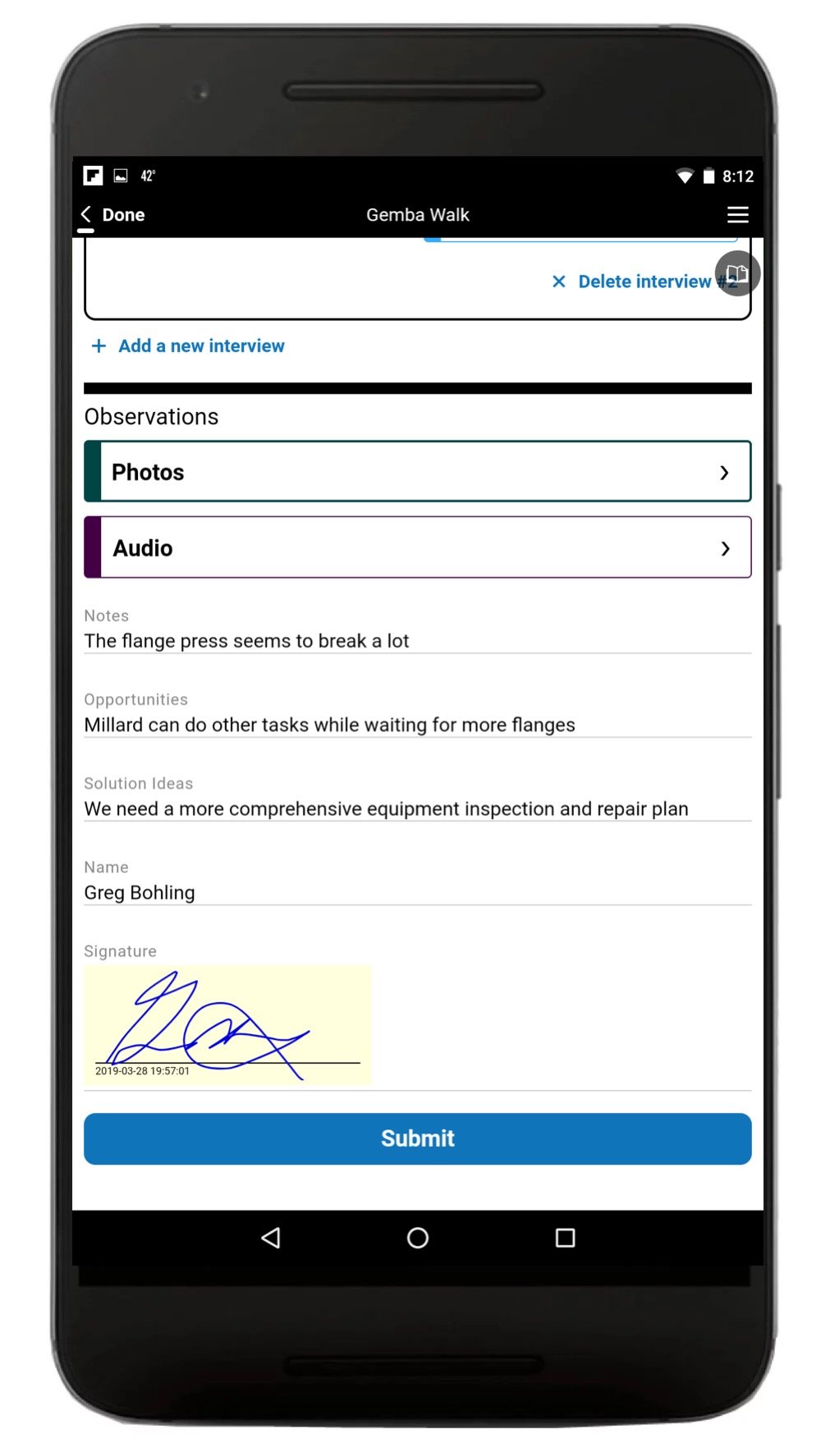

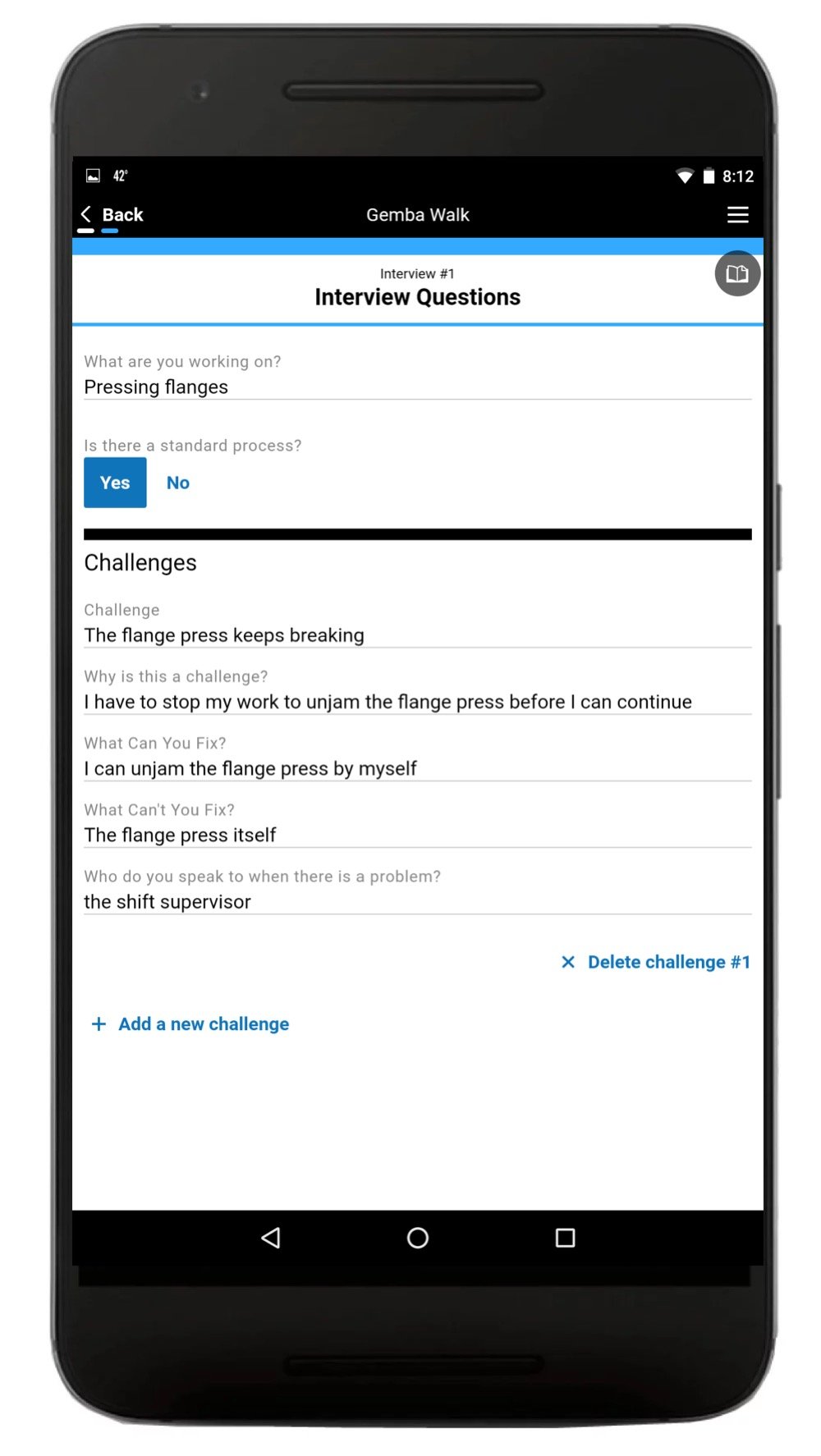

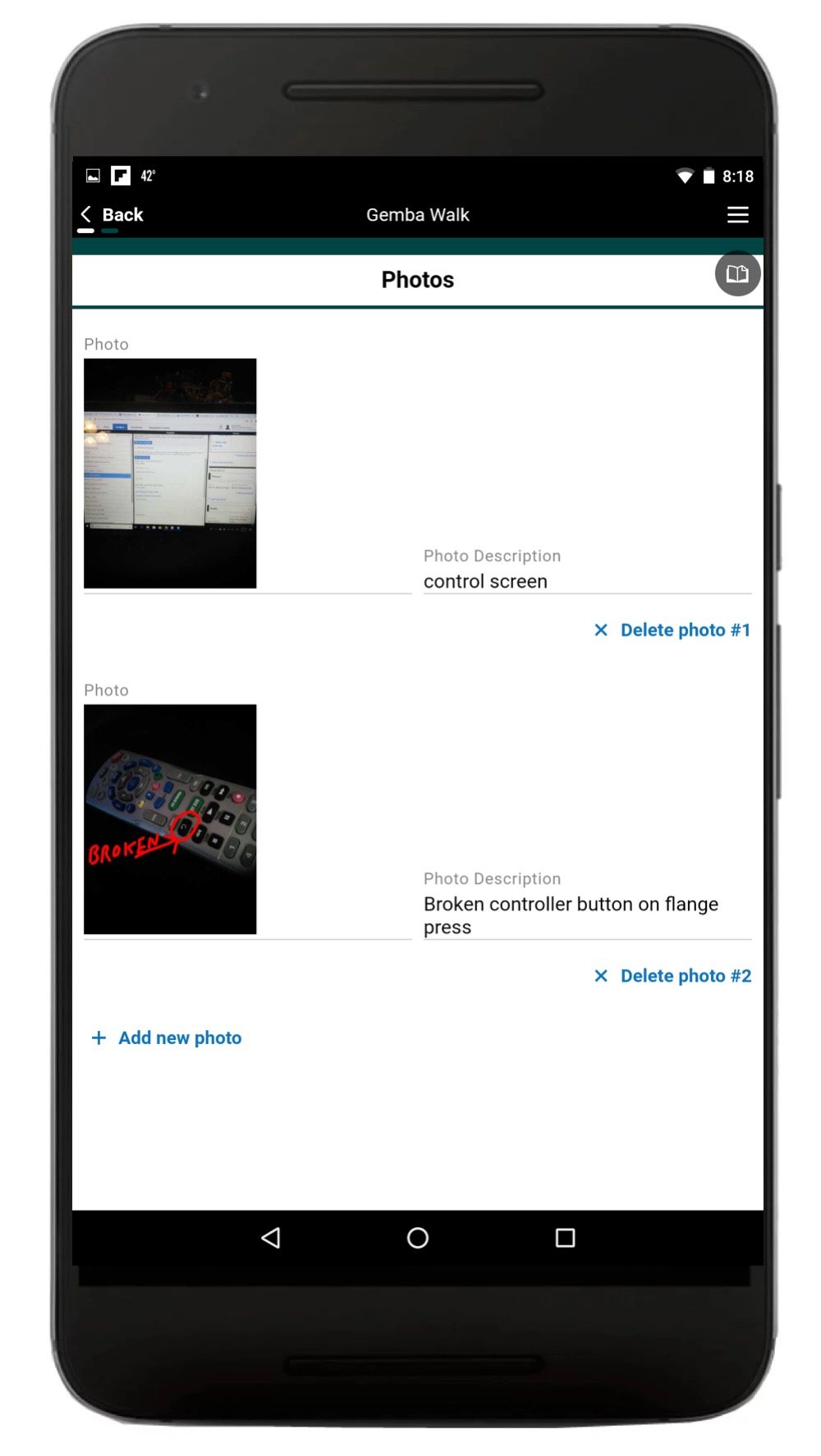

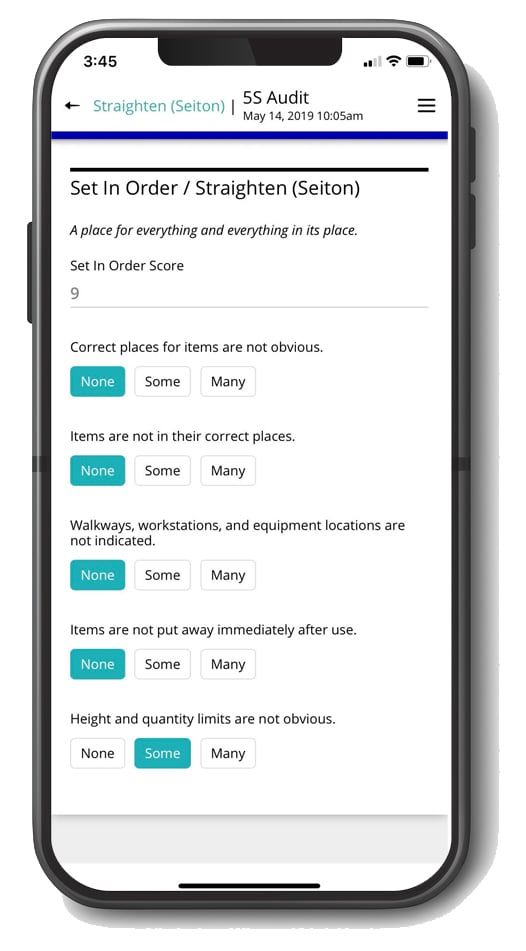

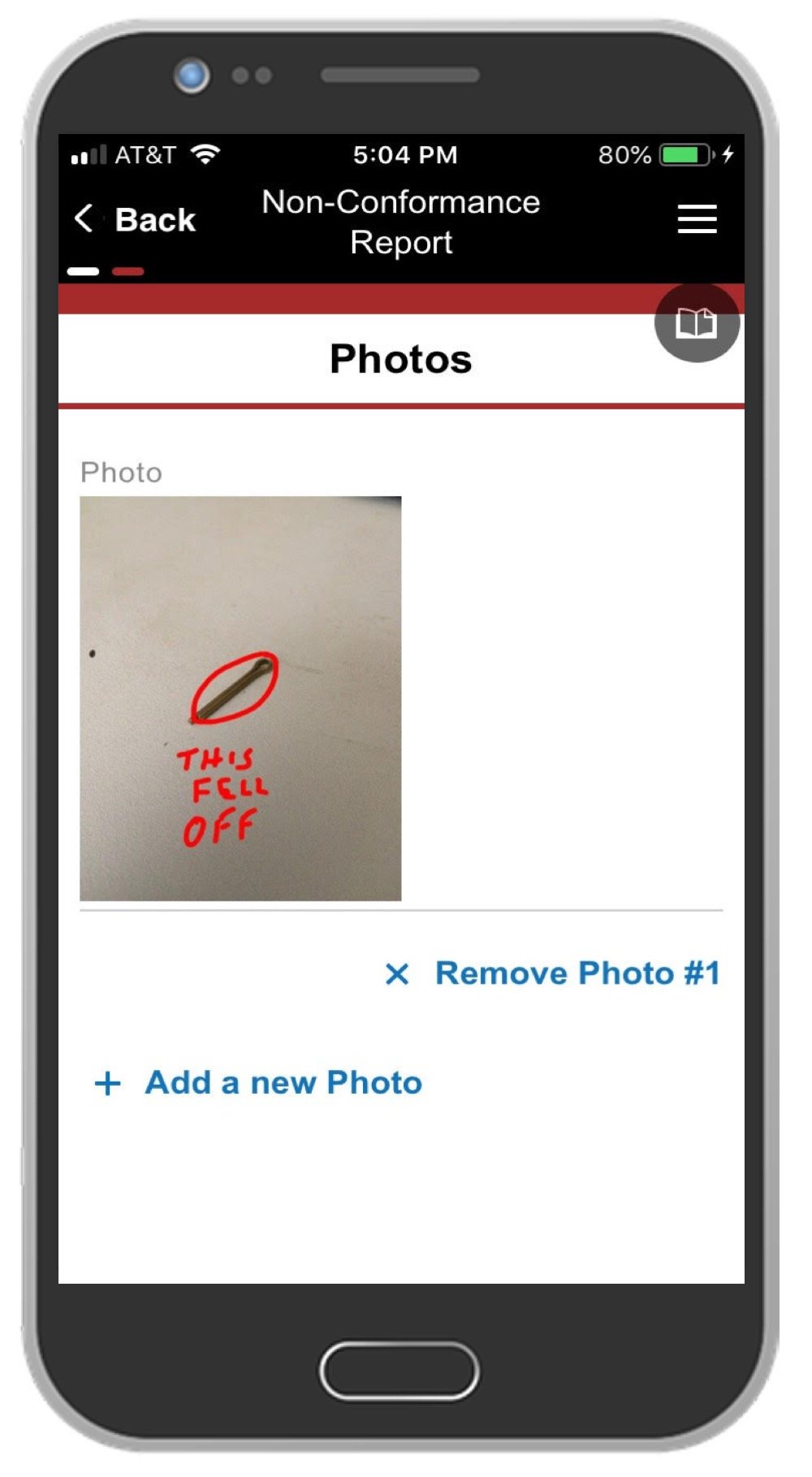

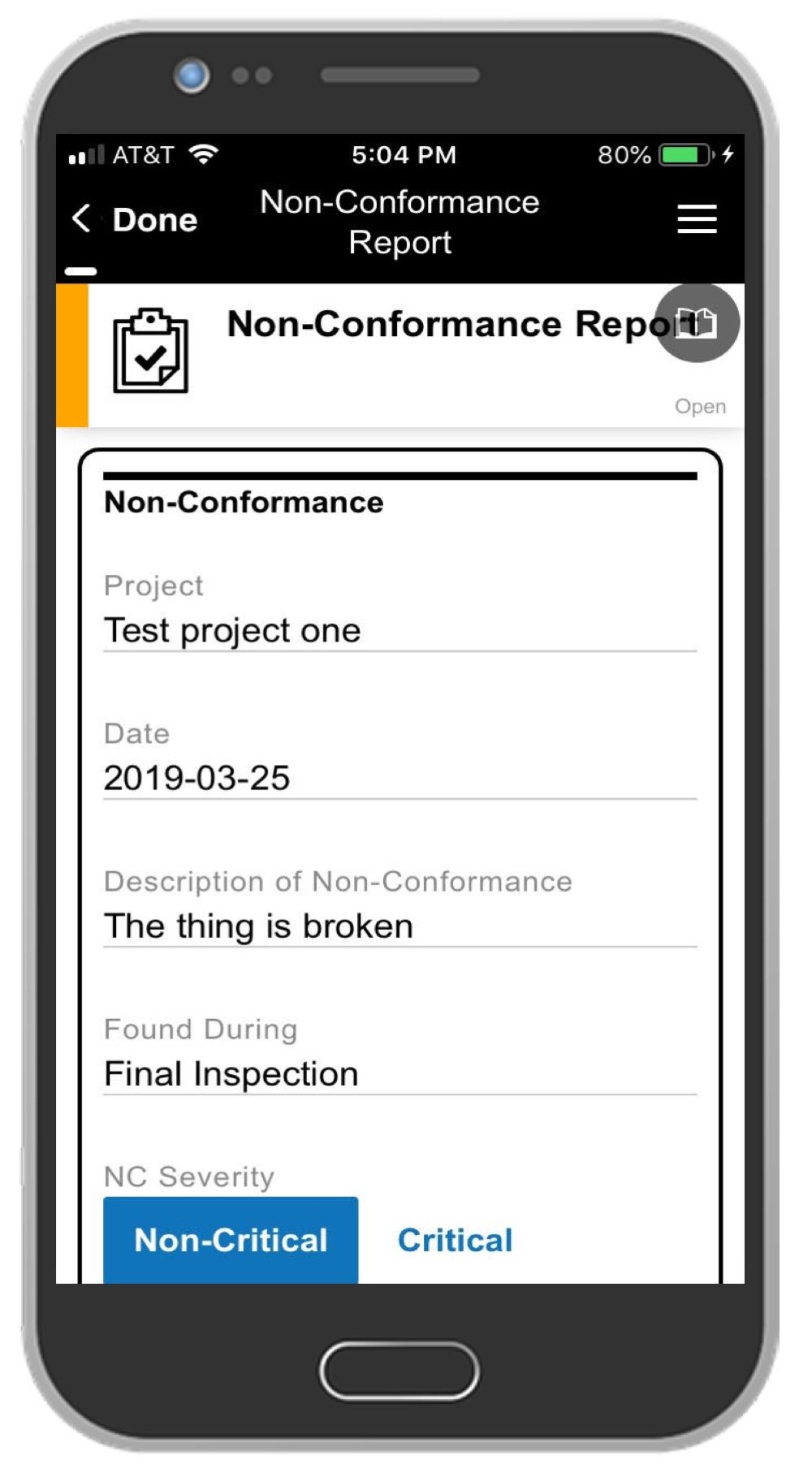

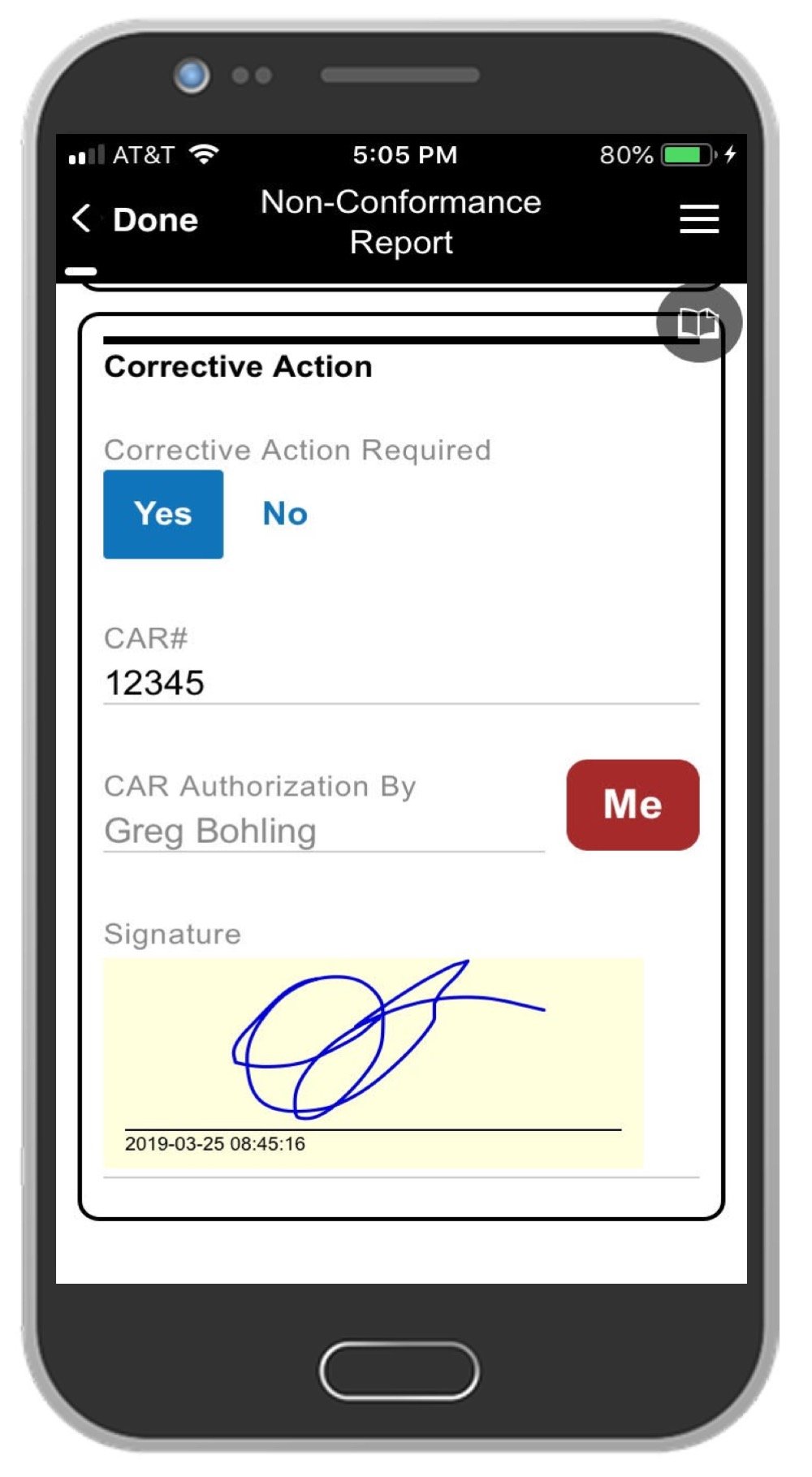

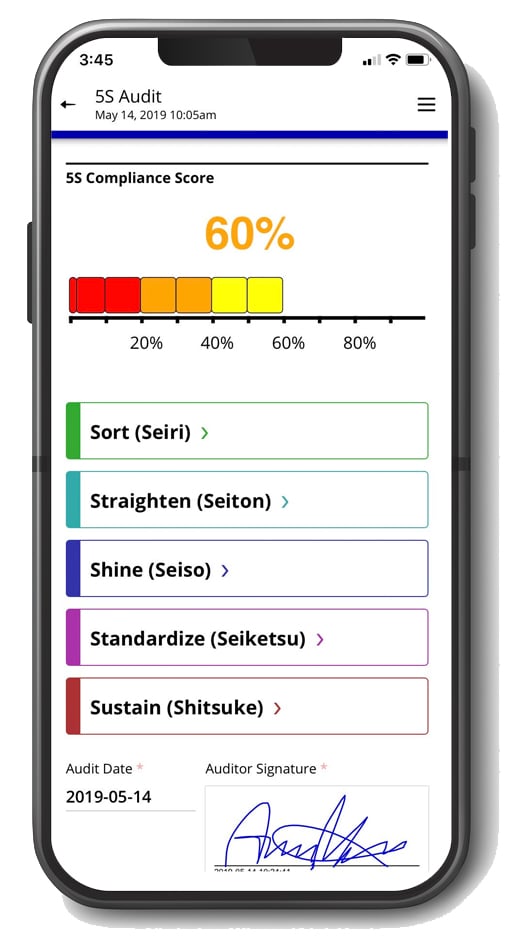

Alpha Software’s Gemba Walk app helps senior management gain insights into manufacturing processes. Its features include audio recording for notes, image capture, with annotation, signature capture, offline functionality, and other drag and drop features.

Alpha’s Gemba Walk app provides access to digital data, and the ability for employees to suggest improvements. Plus users can receive real-time alerts and work collaboratively online or offline.

Kanbanize has a sleek colorful user interface. Features include if-then branching rules, email integration, and time-tracking. Additional features include deeper analytics and inherited card parameters.

KPI Fire is a Lean Six Sigma software that aims to align employees and teams with organizational goals. It combines goal setting & project management with a dashboard interface.

A successful Six Sigma project needs strategic management on board, then to establish goals, gather data, identify the root cause of issues and implement a solution. Solutions like Alpha Gemba Walk and others ease the implementation of any project.

Whether you're a Six Sigma black belt or just getting started, Alpha Software manufacturing solutions will help you better collect, analyze, and leverage your data for continuous improvement.

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/