Quality software is critical for all manufacturers to increase efficiency, save time and reduce the cost of quality. Research shows that using solutions such as computer vision systems, data inspection, and no-code platforms improve the product development process.

Manufacturers recognize that manual processes tend to be more error-prone and drain time and resources. They often prevent manufacturers from maintaining compliance, and quality standards, and demonstrating excellence in process control and quality assurance. Quality control (QC) software and quality assurance (QA) software provides manufacturers with track and trace capabilities, dashboards, productivity, process monitoring, digital checklists, and data monitoring to ensure efficiency and success.

Quality software positively impacts manufacturing processes, supply chain methods, customer service, and maintaining quality systems that comply with regulatory agencies such as ISO. More companies are adopting networked technologies as manufacturers look for an advantage to introduce innovative products and gain an edge over existing competitors.

Low-code, no-code quality software solutions connect people, supply chains, machines, and automated tools. They also track data and provide analytics in real-time, which increases visibility and ensures manufacturers consistently exceed customer expectations.

Many manufacturers digitize their operations, and quality processes to meet quality standards. Selecting the right software is often challenging, as there are multiple options.

Organizations frequently work in highly regulated environments with an extensive range of quality control and quality assurance processes. The right software solution can help manufacturers reduce costs, increase efficiency, and speed up production. Here are some guidelines to follow for using the right software.

Large manufacturers typically have departments that operate in siloed environments. In some cases, they work in separate locations that are miles apart; this makes communication nearly impossible. Process management software provides a centralized platform that opens channels of communication. Employees can assign tasks to each other, communicate quickly, write notes and attach documents.

High-quality manufacturing software solutions automate repetitive and complex routines and tasks, eliminate non-value systems, minimize production bottlenecks, and optimize scheduling. The features of this type of manufacturing system may include order planning, which helps plan and change production schedules.

Inventory management software effectively manages materials across production plants. These solutions ensure that companies have adequate supplies. Some key features of inventory management solutions include procurement management which automatically reorders materials when supplies are low.

Supply chain management ensures the distribution of supplies from raw material suppliers to manufacturers to consumers. Supply chain management software solutions ensure raw materials availability, support communication with suppliers, control purchasing costs, and ensure efficient delivery.

The goal of manufacturing software solutions should be to incorporate quality into processes and predict potential quality issues before production. Quality Management Systems or QMS solutions should eliminate rework, product recalls, and meet customer expectations and strengthen stakeholder confidence, while ensuring products meet quality standards.

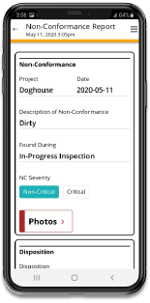

A core element of QMS software is the ability to automate tasks to save time and reduce costs. Automated quality control notifications remind factory floor workers and quality professionals of areas or processes that need extra focus. Non-conformance reports (NCRs) are essential in any quality management solution. Factory workers should have the ability to submit an NCR via their cell phones by taking a picture.

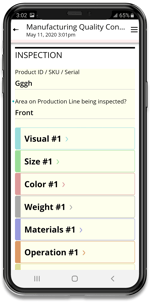

Manufacturing quality software and quality management systems (QMS) show data recorded from reporting, processes, inspections, and quality tests on one screen. The ability to perform quality inspections on a mobile device also saves significant reporting time.

Managing risks is a crucial element of any quality management system platform and fundamental for compliance. An effective quality management solution helps manufacturers’ list risks and connect them to required actions. Manufacturers should ensure they use flexible platforms to support various risk analysis methods such as FMEA or Fine & Ki.

Document management ensures manufacturers lower the chances of having outdated work instructions or procedures. The ability to access documents automatically also helps the quality management process. Medical device manufacturers use digital solutions, quality management software, and mobile applications to reduce reliance on paper-based systems. Many are moving towards automating production processes.

Manufacturers use quality software and solutions to achieve and maintain compliance with ISO 9001 certification and other regulations. They use automated quality processes that can be tailored to specific production processes, operations, and business practices. This enables manufacturers to streamline their quality processes across an entire factory, or multiple plants, depending on the organization's size.

Quality digital solutions integrate quality activities such as standard operating procedures (SOPs), work instructions, key quality indicators (KPIs), and corrective/ preventive actions (CAPA). They also manage supplier relations, quality audits, quality inspections, customer complaints, risk management, and quality control & quality assurance.

Research shows that successfully deploying digital solutions reduces costs of non-quality by 10 to 20 percent. A stack of quality management solutions results in a 50 percent reduction, leading to tremendous opportunities for continual improvement. Oliver Wyman, a managing consulting firm recommends that organizations use digital production tools, a quality feedback loop, mobile device quality testing, and vision control.

A quality feedback loop ensures employees perform their responsibilities effectively and meet quality standards. Machine vision systems use sensors to extract information from digital images to guide manufacturing and quality control procedures. Low-code or no-code solutions enable factory floor employees to use customized manufacturing apps to automate paper-based tasks such as quality inspections and more.

Production lines with many quality defects mean higher costs, drain time, increase rework, and, most importantly, results in costly product recalls. As a result, companies place a high value on visual inspections to reduce product defects. This is where quality control automation solutions gain importance.

Computer vision technology increases the reliability and consistency of quality inspections. Data acquisition software that is used with 3D cameras, hyperspectral cameras, and other sensors provides output processed as images or videos.

Quality planning and quality software are two important parts of improving product quality.

Technology platforms used in manufacturing should serve three functions:

Many quality control teams and shop floor workers use either web or mobile software applications. These mobile device solutions facilitate manufacturing processes and ensure products and services meet quality and regulation standards.

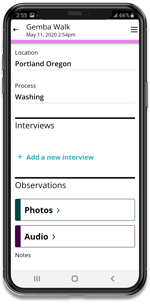

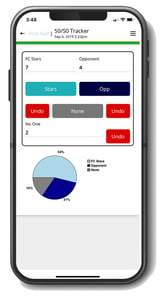

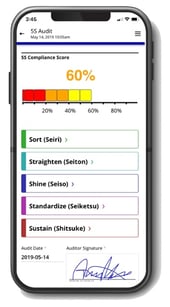

The results of quality inspections and other processes appear in real-time on dashboards or mobile devices. This increases visibility and provides valuable insights to ensure efficient quality control and quality assurance processes. Here are examples of some manufacturing solutions:

Alpha Software

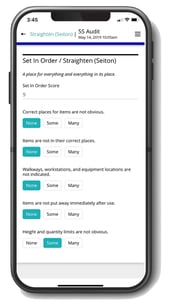

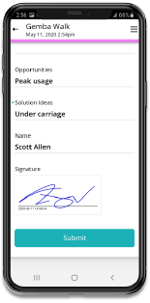

Alpha Software Manufacturing Solutions empowers factory workers, quality teams, and administrative staff with solutions that turn paper-based processes or repetitive tasks into mobile applications with built-in analytics and dashboards. These solutions collect data quickly and provide instant insights on manufacturing processes, potential bottlenecks, and quality issues. The company's offers pre-built solutions for Gemba Walks, 5S Audits, Non-Conformance Reports, Quality Management and more. The solutions can collect manufacturing data on smartphones and tablets, integrate with your existing data sources and workflows, and automate reporting. Alpha receives consistent 5-star reviews on third-party product websites.

Katana

Katana is a visual manufacturing user-friendly ERP that offers manufacturers total visibility of all parts of their business. Manufacturers can monitor critical business processes and activities on one platform across the product lifecycle.

Reviewers say they benefit from Katana's intuitive UI and its capabilities to prioritize orders, create purchase orders, and update and manage inventory. For many users, Katana has saved valuable time and has also been cost effective. Although, some reviewers say that it could be easier to set up, and some key features could be added. Get App Score 4.8.

Poka

Poka's platform which is suitable for manufacturers of all sizes, enables staff training, knowledge sharing, and troubleshooting on the factory floor.

Reviewers liked Poka’s efficiency and its capability to access workflows for any team member who needs them. However, some users found it difficult to work through various procedures and settings. They also noted that Poka involves a long-term process that may take longer to measure true ROI. Get App Score 4.7.

Quality software enables manufacturers to ensure compliance and exceed customer and stakeholder expectations. It also reduces costs, saves valuable time, and makes processes less error-prone. By using computer vision technology, manufacturers achieve greater accuracy in quality inspections.

Alpha Software solutions like those shown below, can dramatically improve productivity, product quality and cost savings. When enterprises embrace efficient, accurate, and result focused practices, they will reap the benefits.

Manufacturing organizations, especially smaller ones, should employ quality management software. Quality assurance and quality control software enhance quality standards while raising production levels and customer satisfaction, according to studies. When employed for preventative measures, it can help lower the cost of quality efforts. According to research, quality management software has a high return on investment, eliminates errors, and promotes continuous development throughout the organization.

The Alpha platform is the only unified mobile and web app development and deployment environment with distinct “no-code” and “low-code” components. Using the Alpha TransForm no-code product, business users and developers can take full advantage of all the capabilities of the smartphone to turn any form into a mobile app in minutes, and power users can add advanced app functionality with Alpha TransForm's built-in programming language. IT developers can use the Alpha Anywhere low-code environment to develop complex web or mobile business apps from scratch, integrate data with existing systems of record and workflows (including data collected via Alpha TransForm), and add additional security or authentication requirements to protect corporate data.

Alpha Software Corporation, based in Massachusetts, produces award-winning software that speeds mobile and web app development and deployment for business and IT. The core technology includes two components. Alpha Anywhere®, a full-stack low-code app development platform for building and deploying web and mobile apps. In just hours, Alpha TransForm® turns complex paper forms into powerful mobile forms that speed data collection.

Alpha Software is an InfoWorld Technology of the Year award winner, and scores near-perfect reviews from customers on crowdsourced review sites.

Customers rate Alpha Software highly for its speed of development, flexibility, offline apps, rich feature set and ability to scale predictably. For more information, visit https://www.alphasoftware.com/